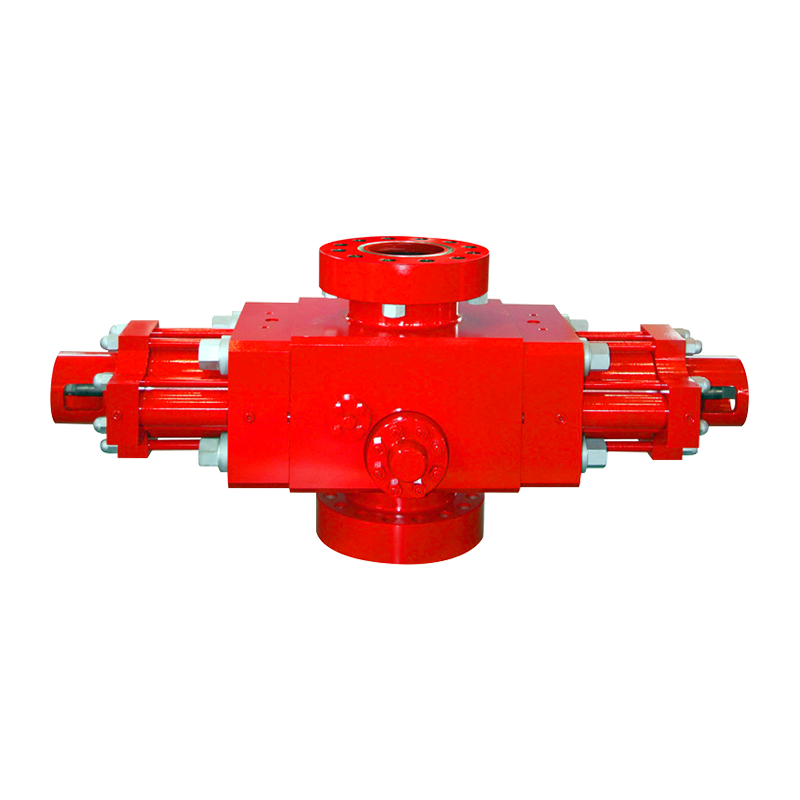

At the beginning of the design of Frac Head, engineers conducted in-depth analysis and research on every aspect of the fracturing operation. They know that fluid pressure changes are one of the most core and sensitive factors in fracturing operations. Therefore, how to accurately capture and provide real-time feedback of these pressure changes has become the primary task of sensor layout.

In order to achieve this goal, engineers used advanced simulation technology to conduct detailed simulation analysis of the fluid flow inside the Frac Head. They found that the pressure changes of the fluid showed significant differences when flowing through different paths, and these differences were the key to determining the placement of the sensors. Based on this discovery, engineers began planning the layout of the sensors.

During the sensor layout process, engineers followed the principle of “comprehensive coverage and focused monitoring”. They arranged high-precision sensors at critical path points of the fluid based on the characteristics of the fluid flow and the law of pressure changes. These sensors, like nerve endings, can keenly capture small changes in fluid pressure and convert them into electrical signals for transmission to the control system. Specifically, sensors are arranged at fluid inlets, outlets, and key nodes through which fluid flows. At the fluid inlet, the sensor is responsible for monitoring the initial pressure of the fluid entering the Frac Head, providing baseline data for subsequent pressure adjustment; at the fluid outlet, the sensor monitors the pressure of the fluid flowing out of the Frac Head to ensure that the pressure fluctuates within a reasonable range; while at the fluid flow At key nodes, sensors are responsible for capturing the details of pressure changes and providing a more accurate basis for adjustment of the control system.

The layout of the Frac Head sensor not only reflects the engineers’ deep understanding and insight into fracturing operations, but also incorporates a number of technological innovations. For example, in terms of sensor selection, engineers used pressure sensors with high sensitivity and high stability to ensure the accuracy and reliability of data; in terms of data transmission, high-speed wireless transmission technology was used to realize the connection between sensors and Real-time communication between control systems greatly improves the efficiency and stability of data transmission. In addition, engineers also fully considered the maintenance and upkeep of sensors. They designed a sensor installation structure that is easy to disassemble and replace, so that when the sensor fails or needs calibration, it can be quickly replaced or repaired, thus ensuring the continuity and stability of fracturing operations.

+ 86-0515-88429333

+ 86-0515-88429333