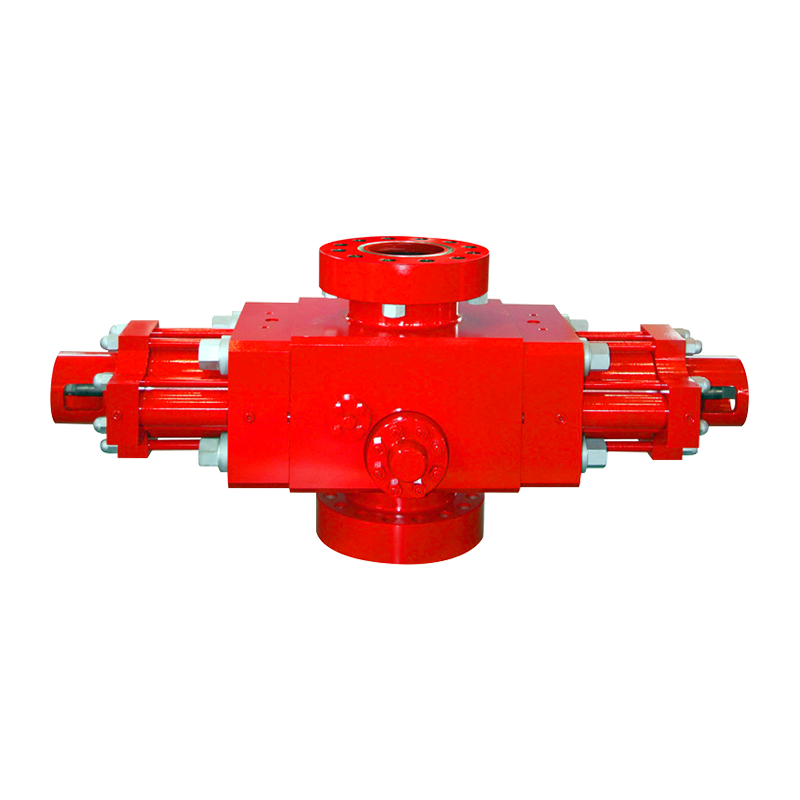

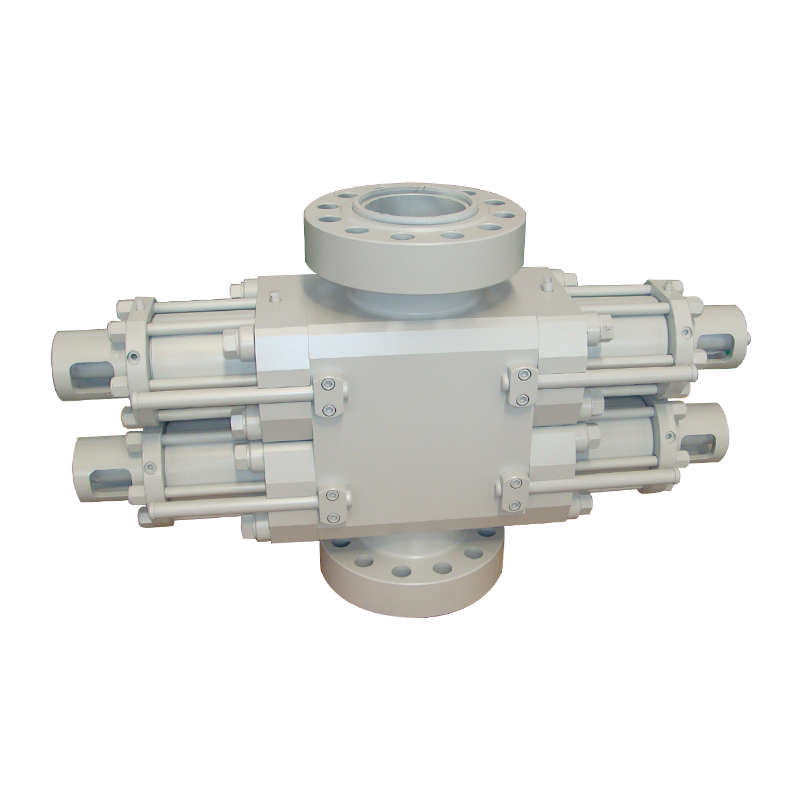

The core function of H2 Choke (Positive) Stationary Choke Valve is to accurately regulate and control the flow and pressure of hydrogen. Its original design was to meet the needs of high-pressure, high-purity hydrogen application scenarios such as hydrogen energy vehicle refueling stations. By adopting high-strength, corrosion-resistant materials and advanced manufacturing processes, the valve can maintain stable performance under extreme conditions to ensure the safe transmission and refueling of hydrogen.

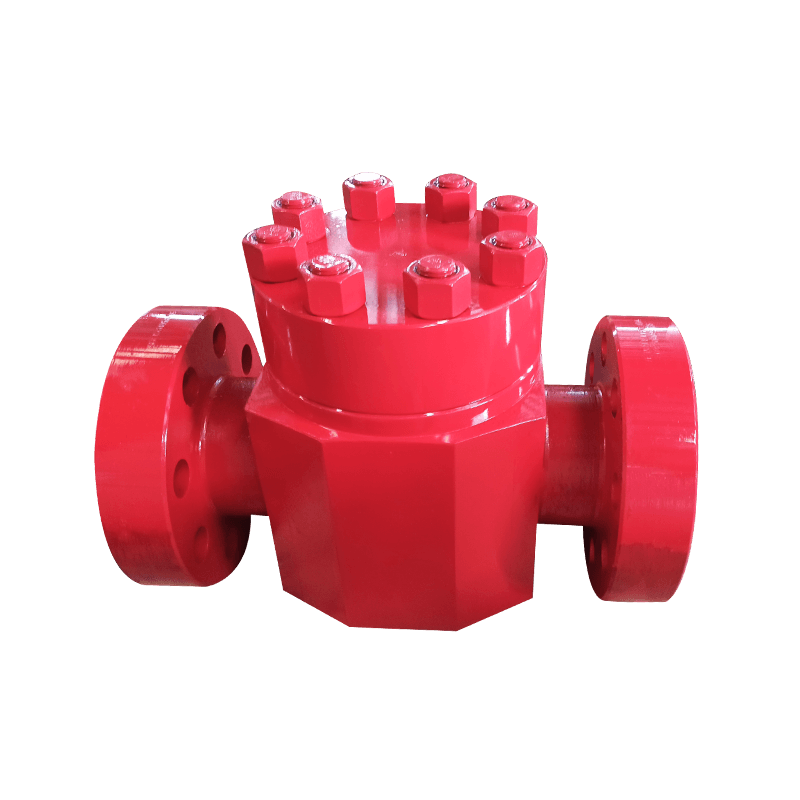

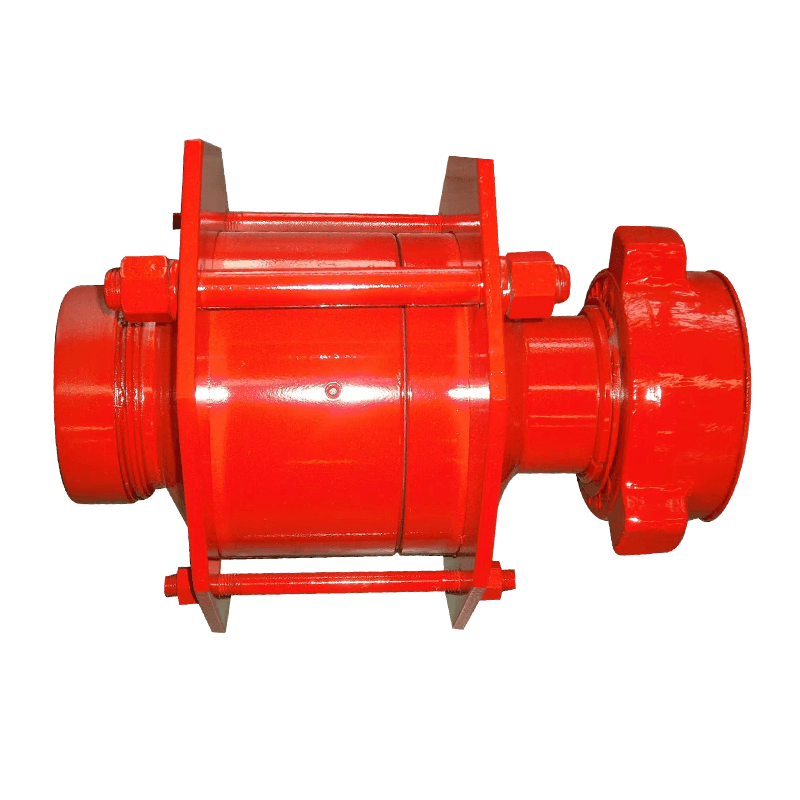

The structural design of the valve fully considers the special properties of hydrogen, such as low density, high diffusivity and flammability and explosiveness. Therefore, key components such as the valve body, valve seat and valve core are made of high-quality stainless steel or alloy steel materials, which not only have excellent pressure resistance and corrosion resistance, but also maintain stable mechanical properties at high temperatures. In addition, the sealing structure of the valve is also carefully designed to ensure good sealing under high pressure environment to prevent hydrogen leakage.

In hydrogen fueling stations for hydrogen vehicles, H2 Choke (Positive) Stationary Choke Valve is widely used in hydrogen refueling machine systems and hydrogen storage systems. It achieves a smooth, efficient and safe hydrogen refueling process by precisely controlling the flow and pressure of hydrogen. Compared with traditional flow control equipment, this valve has higher precision and reliability, which can significantly improve the operational efficiency and customer satisfaction of hydrogen refueling stations.

In addition, H2 Choke (Positive) Stationary Choke Valve also has the following advantages:

Efficiency: By quickly adjusting the flow and pressure of hydrogen, the refueling time is shortened and the hydrogen refueling efficiency is improved.

Safety: The use of high-strength materials and advanced sealing technology ensures that there are no safety issues such as leakage under high-pressure environments.

Maintainability: The reasonable structural design facilitates daily maintenance and reduces operating costs.

Environmental protection: As part of the hydrogen energy industry, the application of this valve helps promote the development of clean energy and reduce pollution to the environment.

Meeting challenges and future development

Although H2 Choke (Positive) Stationary Choke Valve plays an important role in the hydrogen energy industry, it still faces some challenges. For example, with the rapid development of the hydrogen energy industry, the requirements for valve performance and quality are also increasing. Therefore, manufacturers need to continuously innovate and improve technology to meet market demand.

At the same time, with the expansion of hydrogen energy application scenarios and the maturity of technology, H2 Choke (Positive) Stationary Choke Valve is expected to be used in more fields. For example, in hydrogen power plants, hydrogen energy storage facilities, and industrial hydrogen, this valve will play an important role.

Web Menu

Product Search

Exit Menu

News

Home / News / Industry news / How does H2 Choke (Positive) Stationary Choke Valve, a flow control expert in the field of hydrogen energy, lead the new era of clean energy?

How does H2 Choke (Positive) Stationary Choke Valve, a flow control expert in the field of hydrogen energy, lead the new era of clean energy?

If you are interested in our products, please consult us

Contact Details

- Address: No.588 Century Street,Yandu District, Yancheng City,Jiangsu Province PR China

- Wechat/What's app:+86-15895199590

- Mobilephone No:+86-18066199608

- Email: Sales03@wellhead.cn

Products

Quick Link

News Center

Mobile terminal

+ 86-0515-88429333

+ 86-0515-88429333