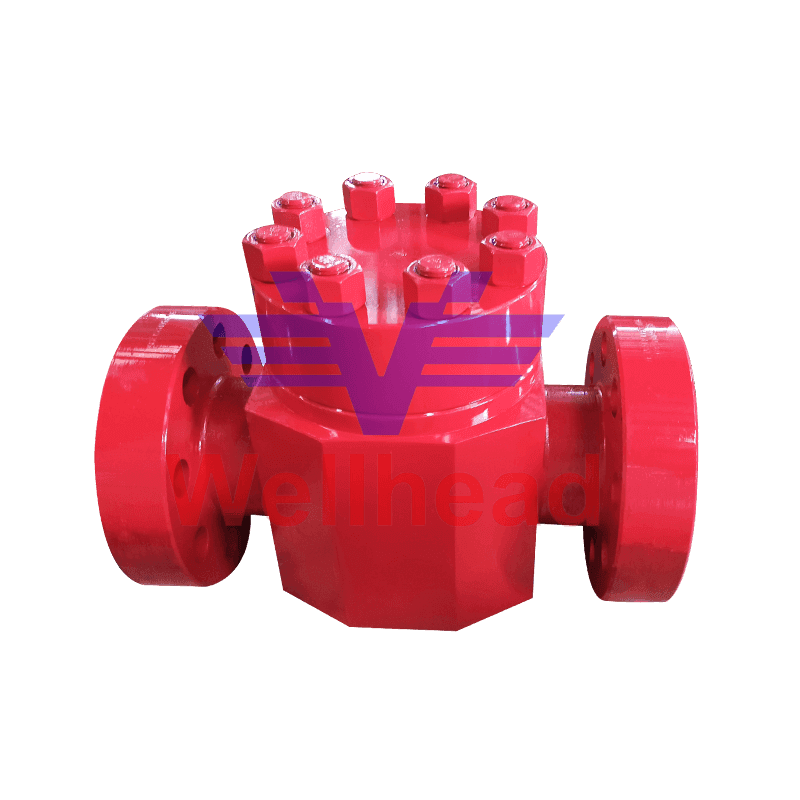

The sealing performance of FLSR Ball Screw Operated Gate Valve is guaranteed by comprehensive measures in many aspects. FLSR Ball Screw Operated Gate Valve adopts high temperature resistant, corrosion resistant and wear resistant sealing materials, such as polytetrafluoroethylene (PTFE), RPTFE (reinforced polytetrafluoroethylene) or para-polyphenylene. These materials can still maintain stable performance under high pressure, high temperature and corrosive media environment. For example, PTFE has excellent chemical stability and low friction coefficient, while RPTFE enhances mechanical properties and wear resistance on the basis of PTFE, thereby improving the sealing effect.

FLSR Ball Screw Operated Gate Valve adopts spherical sealing surface design, which can ensure that the sealing surface forms a more uniform contact pressure when in contact, thereby improving the sealing performance. The sealing seat may adopt an elastic sealing structure, such as a sealing seat with elastic elements or a combined sealing seat. These structures can produce a certain elastic-plastic deformation under the action of the medium pressure, form the necessary sealing pressure ratio, and ensure the sealing effect. In order to ensure the sealing performance when the working pressure of the medium is low, a certain pre-tightening pressure ratio must be formed between the ball and the sealing seat. The selection and adjustment of the preload ratio are crucial for sealing performance.

The matching accuracy between the ball and the sealing surface has an important influence on the sealing performance. By improving the processing accuracy and reducing the surface roughness, the contact quality and sealing performance of the sealing surface can be improved. The maximum allowable value of the roughness Ra value of the ball sealing surface is 0.4μm, and the maximum allowable value of the roughness Ra value of the sealing seat is 0.8μm when polytetrafluoroethylene is used as the sealing material. Such surface finish helps to reduce leakage.

Regular maintenance and inspection of the FLSR Ball Screw Operated Gate Valve, including checking the wear of the sealing surface, replacing the seals and valve seats with severe wear, etc., are important measures to maintain its sealing performance. When operating the valve, follow the correct operating procedures and avoid improper operating behaviors such as excessive opening and closing, impact and vibration to prevent damage to the sealing structure.

Some valves may be designed with anti-explosion devices, such as the valve stem adopts a bottom-mounted structure with an inverted seal to ensure that the valve stem will not be flushed out when the valve cavity is abnormally pressurized. The installation position of the valve will also affect its sealing performance. Try to avoid installing it in places with large vibration, impact and temperature changes to ensure the stability of its sealing performance.

FLSR spherical thread gate valves ensure their excellent sealing performance by selecting high-quality sealing materials, designing precise sealing structures, improving processing accuracy and surface finish, regular maintenance and inspection, and optimizing design and installation positions. These measures work together to ensure that FLSR spherical thread gate valves can maintain a stable sealing effect under various harsh working conditions.

News

Home / News / Industry news / How is the sealing performance of FLSR Ball Screw Operated Gate Valve guaranteed?

How is the sealing performance of FLSR Ball Screw Operated Gate Valve guaranteed?

If you are interested in our products, please consult us

Contact Details

- Address: No.588 Century Street,Yandu District, Yancheng City,Jiangsu Province PR China

- Wechat/What's app:+86-15895199590

- Mobilephone No:+86-18066199608

- Email: Sales03@wellhead.cn

- Sales@wellhead.cn

Products

Quick Link

News Center

Mobile terminal

+ 86-0515-88429333

+ 86-0515-88429333