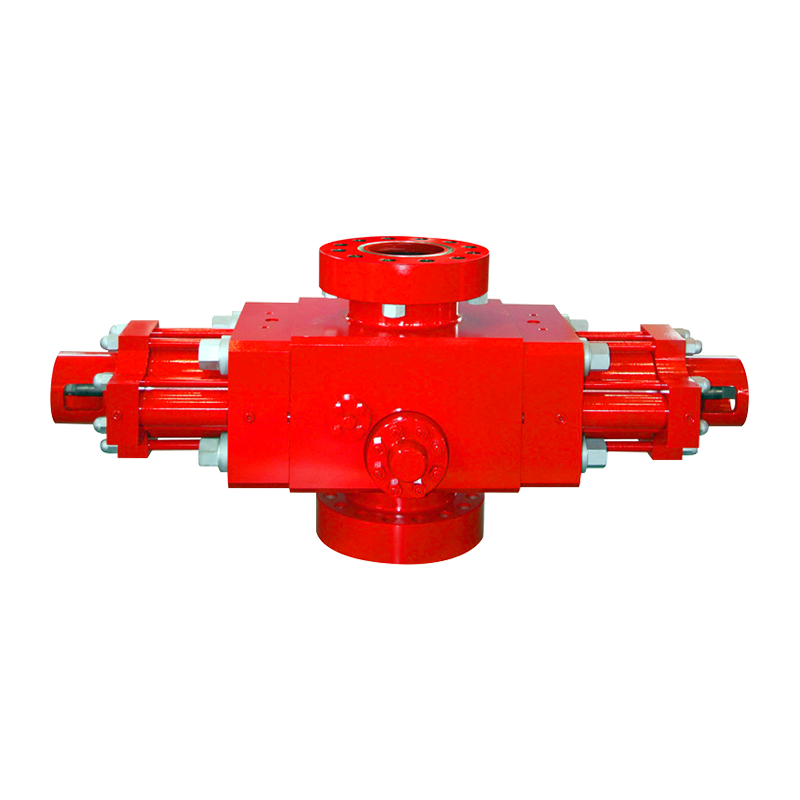

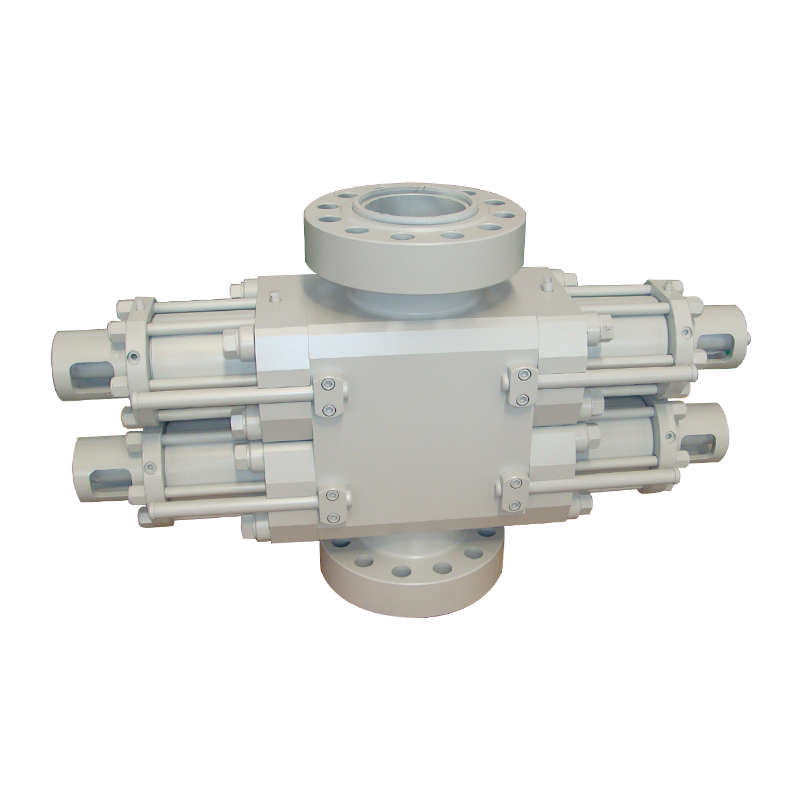

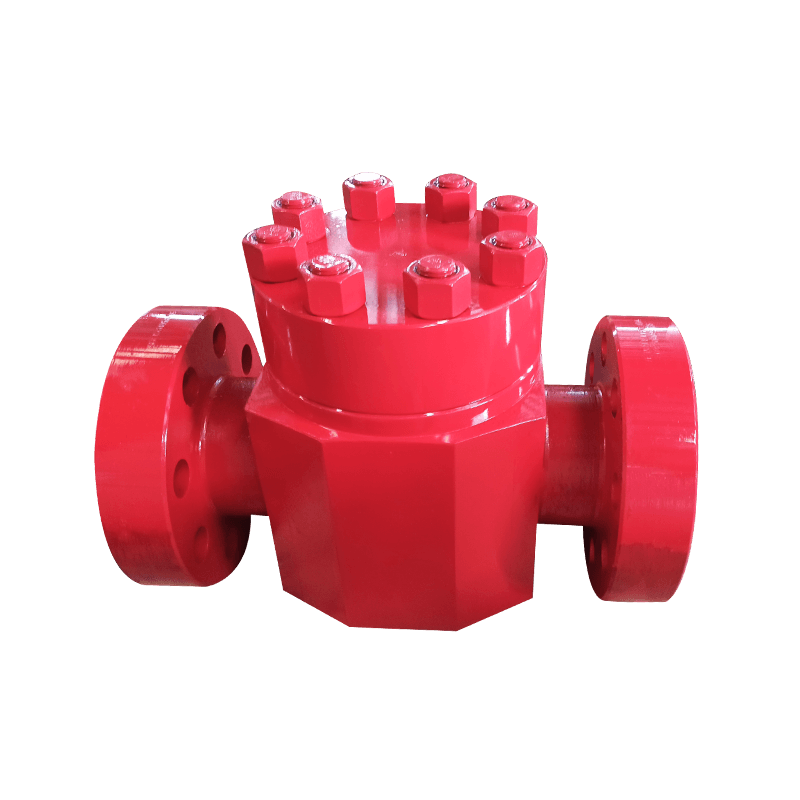

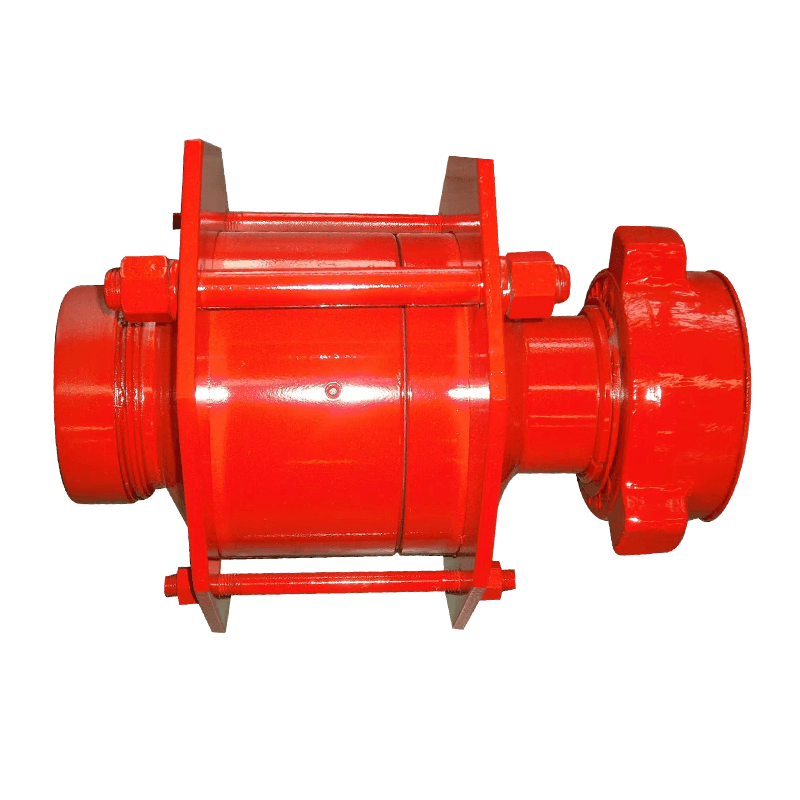

H2 Adjustable Choke Valve can control fluid flow and pressure more accurately through its highly adjustable design. This accuracy is particularly important in high-temperature and high-pressure steam environments because it ensures that the flow and pressure of steam are always kept within the set safety range to avoid equipment damage or safety accidents caused by pressure fluctuations.

The valve is designed with special materials and structures to withstand the working environment of high-temperature and high-pressure steam. These materials generally have good high-temperature resistance, corrosion resistance and wear resistance, allowing the valve to operate stably for a long time under high-temperature and high-pressure conditions.

H2 Adjustable Choke Valve focuses on stability and reliability during design and manufacturing. Its internal structure has been optimized to reduce the vibration and noise caused by the impact of high-temperature and high-pressure steam, and improve the overall stability and service life of the valve. At the same time, the valve is also equipped with an advanced sealing system to effectively prevent steam leakage and ensure the safe operation of the system.

H2 Adjustable Choke Valve is not only suitable for high-temperature and high-pressure steam environments, but also for a variety of fluid media, including corrosive liquids. This wide range of applicability makes the valve widely used in many industries such as petroleum, chemical, electric power, and pharmaceuticals.

Compared with traditional throttle valves, the H2 Adjustable Choke Valve is easier to maintain and adjust. Its design takes into account the operating habits and needs of maintenance personnel, making the maintenance and adjustment process faster and more efficient.

+ 86-0515-88429333

+ 86-0515-88429333