In the realm of well stimulation, frac heads play a crucial role in ensuring the precise distribution of pressure and fluid.

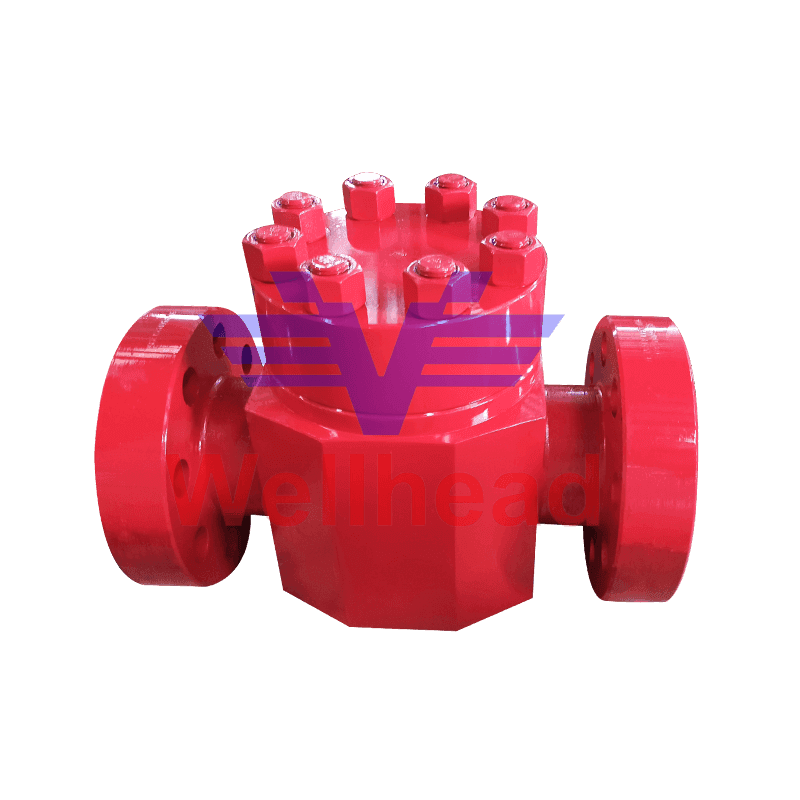

Frac heads are engineered with a complex network of internal channels and valves. These channels are designed to direct the high-pressure fluid, which typically consists of a mixture of water, proppants, and chemicals, to the various zones of the wellbore. The valves within the frac head control the flow rate and direction of the fluid, allowing for fine-tuned adjustments. For example, in a multi-zone well, the frac head can be configured to deliver different amounts of fluid and pressure to each zone based on its specific requirements. This is achieved through a combination of adjustable choke valves and pressure sensors.

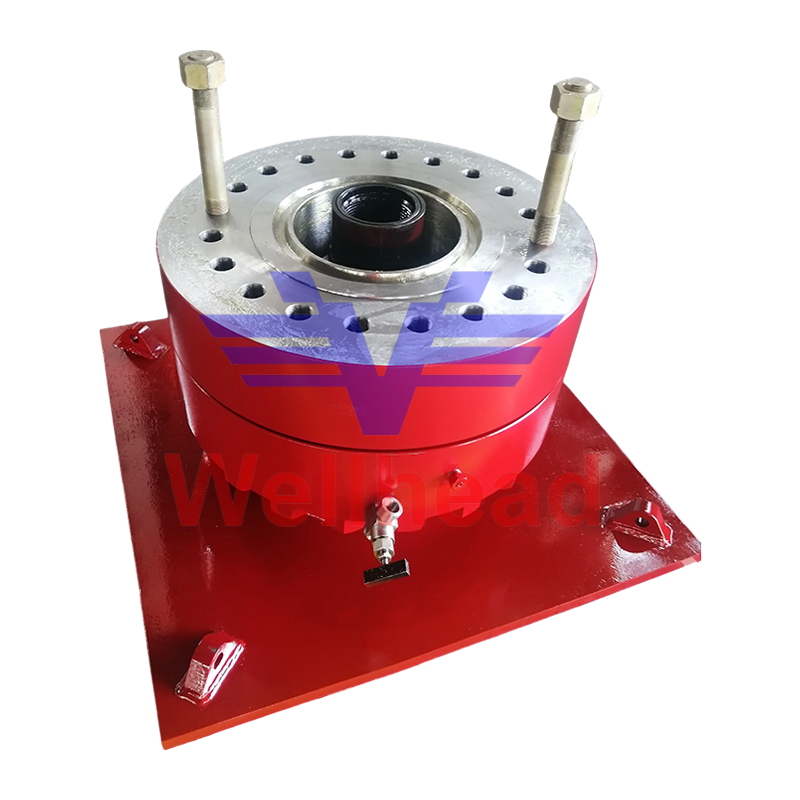

The sealing mechanisms in frac heads are also of utmost importance. They prevent any leakage of the high-pressure fluid, ensuring that the intended pressure is maintained within the wellbore. High-quality seals made from materials that can withstand the harsh downhole conditions, such as extreme pressure and temperature, are used. This not only protects the integrity of the well but also maximizes the efficiency of the stimulation process.

Moreover, frac heads are often equipped with advanced monitoring and control systems. These systems continuously measure the pressure and flow rate of the fluid at different points within the frac head. Based on this real-time data, the operators can make immediate adjustments to optimize the distribution of pressure and fluid. For instance, if the pressure in a particular zone is too high or too low, the control system can adjust the valves to correct the imbalance.

News

Home / News / Industry news / How Do Frac Heads Ensure the Proper Distribution of Pressure and Fluid in Well Stimulation?

How Do Frac Heads Ensure the Proper Distribution of Pressure and Fluid in Well Stimulation?

If you are interested in our products, please consult us

Contact Details

- Address: No.588 Century Street,Yandu District, Yancheng City,Jiangsu Province PR China

- Wechat/What's app:+86-15895199590

- Mobilephone No:+86-18066199608

- Email: Sales03@wellhead.cn

- Sales@wellhead.cn

Products

Quick Link

News Center

Mobile terminal

+ 86-0515-88429333

+ 86-0515-88429333