In the complex and demanding field of oil and gas applications, frac heads play a vital role in the hydraulic fracturing process. The differences between standard and custom frac heads can have a significant impact on the efficiency, safety, and overall success of operations.

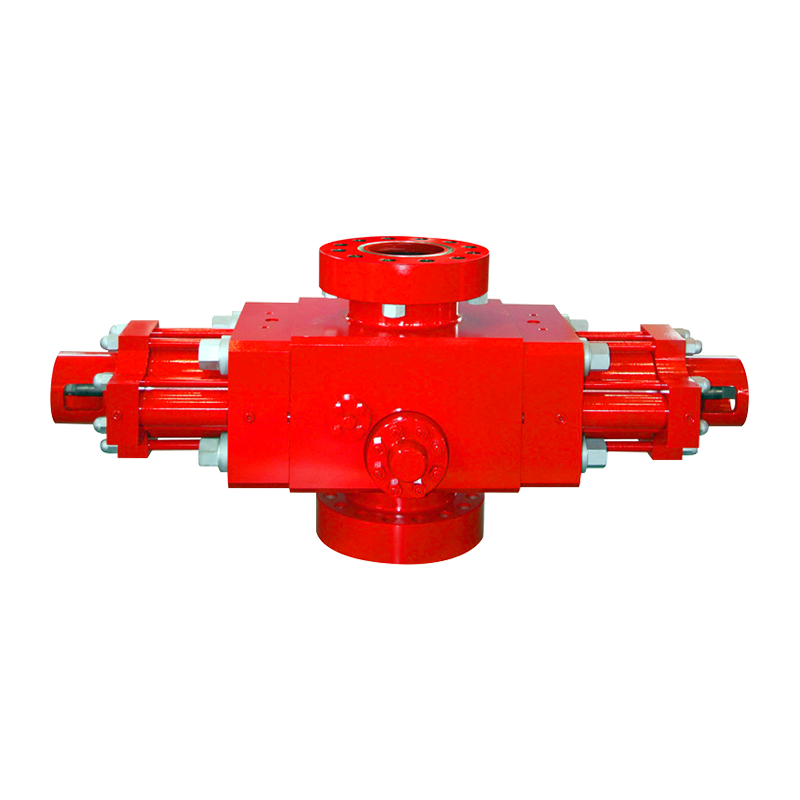

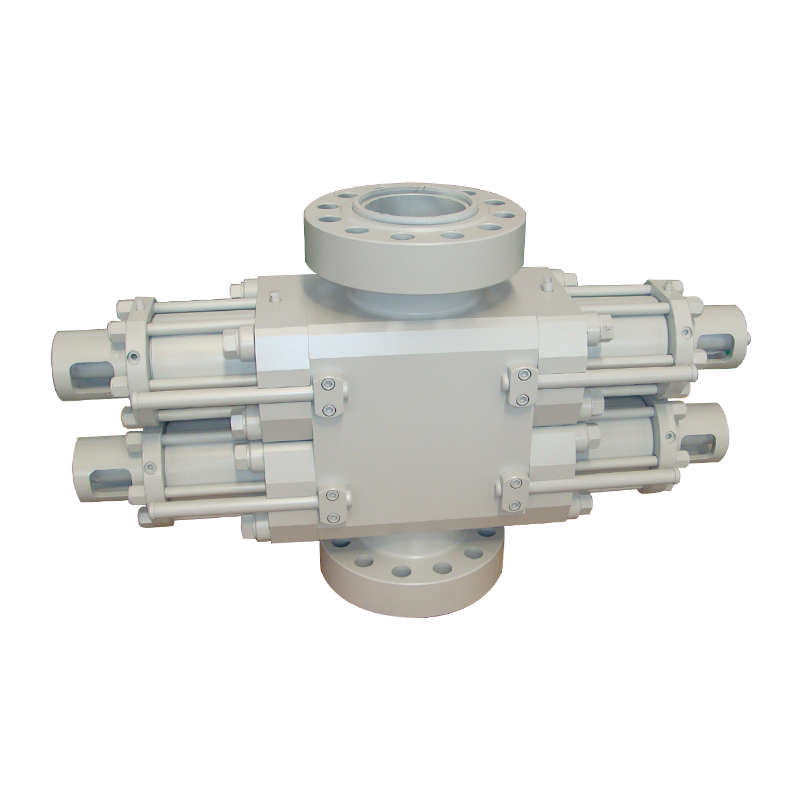

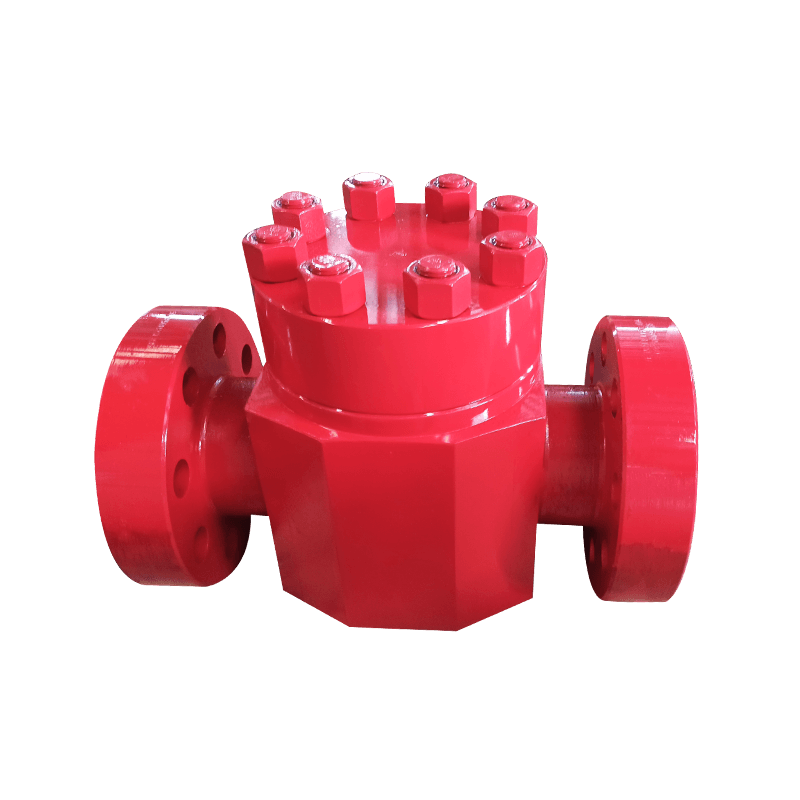

Standard frac heads are designed to meet the general requirements of most common hydraulic fracturing scenarios. They are mass-produced and offer a set of standardized features and specifications. One of the main advantages of standard frac heads is their cost-effectiveness. Since they are produced in large quantities, the manufacturing costs are spread out, making them more affordable for many operators. They typically have a fixed design in terms of size, pressure rating, and connection types. For example, a standard frac head may have a specific nominal diameter and be rated for a certain maximum pressure, which is suitable for a wide range of typical well conditions.

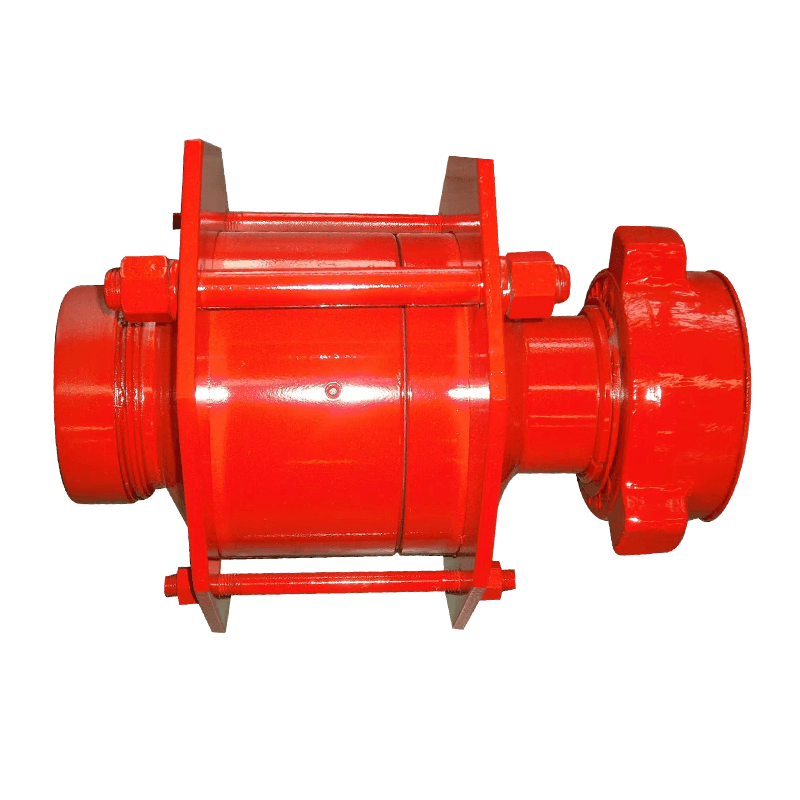

However, custom frac heads are tailored to meet the unique and specific needs of individual projects or well sites. These may be required when dealing with unconventional reservoirs, extreme well depths, or special geological formations. Custom frac heads can be designed with different materials to withstand specific corrosive environments or high-pressure conditions. For instance, in a well with highly acidic fluids, a custom frac head made from corrosion-resistant alloys can be fabricated. They also offer flexibility in terms of size and shape. If a well has a limited space for installation or requires a particular flow path design, a custom frac head can be engineered to fit precisely.

In terms of functionality, custom frac heads can be equipped with additional features that are not available in standard models. This could include advanced pressure monitoring and control systems, multiple injection points for different types of fluids or additives, or specialized sealing mechanisms to prevent leaks in challenging conditions. For example, in a complex multi-stage fracturing operation, a custom frac head with multiple injection ports and independent pressure control for each stage can enhance the effectiveness of the treatment.

Safety is another crucial aspect where differences exist. Custom frac heads can be designed with enhanced safety features such as redundant pressure relief valves, improved emergency shutdown systems, or reinforced structural components to handle higher stress levels. While standard frac heads also meet safety regulations, custom ones can go above and beyond to address specific safety concerns related to a particular project.

Web Menu

Product Search

Exit Menu

News

Home / News / Industry news / What Are the Key Differences Between Standard and Custom Frac Heads in Oil and Gas Applications?

What Are the Key Differences Between Standard and Custom Frac Heads in Oil and Gas Applications?

If you are interested in our products, please consult us

Contact Details

- Address: No.588 Century Street,Yandu District, Yancheng City,Jiangsu Province PR China

- Wechat/What's app:+86-15895199590

- Mobilephone No:+86-18066199608

- Email: Sales03@wellhead.cn

Products

Quick Link

News Center

Mobile terminal

+ 86-0515-88429333

+ 86-0515-88429333