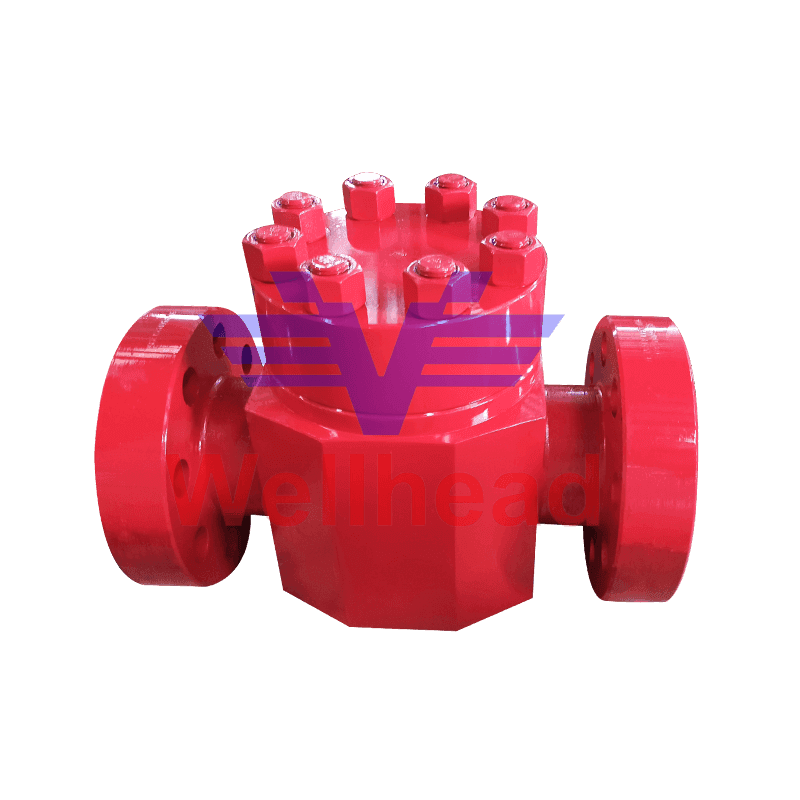

With its unique plug plate structure, High Pressure Plug Valve can achieve reliable opening and closing operation under high pressure environment. The plug plate is usually made of high-strength, corrosion-resistant materials, which can withstand pressure fluctuations and medium erosion under different working conditions. The introduction of hydraulic actuators has greatly improved the operating efficiency and automation level of valves. The hydraulic actuator uses the incompressibility and high transmission force of the liquid to generate huge driving force in a short time, and quickly pushes the plug plate to complete the opening and closing action.

In order to achieve efficient and precise control, High Pressure Plug Valve with Hydraulic Actuator is equipped with an advanced automatic control system. The system adopts a hierarchical control structure, including bottom-level execution control, middle-level logic control and upper-level monitoring management. The valve status and system parameters are monitored in real time through high-precision sensors, and the data is fed back to the controller. The controller uses advanced control algorithms (such as PID control, fuzzy control, etc.) to accurately adjust the action of the hydraulic actuator to ensure that the valve can be opened and closed according to the preset trajectory and speed. At the same time, the system also has remote monitoring and diagnosis functions, which makes it easy for operators to grasp the valve operation status in real time and conduct remote intervention.

Sealing performance is one of the core indicators of High Pressure Plug Valve with Hydraulic Actuator. In order to ensure its sealing performance, the design team carefully considered and optimized in many aspects. First, high-pressure and wear-resistant sealing materials such as polytetrafluoroethylene (PTFE) and its modified materials were selected, which have good chemical corrosion resistance, wear resistance and extrusion resistance. Secondly, reasonable sealing structure design, such as multiple sealing structure and self-tightening sealing structure, is adopted to meet different working conditions. In addition, through high-precision processing and strict quality control, the dimensional accuracy and surface roughness of the sealing surface are ensured to meet the requirements. Finally, regular maintenance and maintenance of the valve and timely replacement of severely worn seals are also important measures to ensure sealing performance.

High Pressure Plug Valve with Hydraulic Actuator has broad application prospects in industries such as petroleum, natural gas, chemical industry and power. In the process of oil and gas extraction, this valve can ensure the safe operation and efficient transportation of oil and gas pipelines; in chemical production, it can control the flow of various corrosive media to ensure the continuity and stability of the production process; in the power industry, the high-pressure plug valve is an indispensable safety barrier in nuclear power plants and other nuclear energy facilities. Therefore, it can be said that the performance stability and reliability of the High Pressure Plug Valve with Hydraulic Actuator are directly related to the safety and stable operation of the entire industrial system.

News

Home / News / Industry news / How does High Pressure Plug Valve with Hydraulic Actuator ensure its good performance and sealing guarantee?

How does High Pressure Plug Valve with Hydraulic Actuator ensure its good performance and sealing guarantee?

If you are interested in our products, please consult us

Contact Details

- Address: No.588 Century Street,Yandu District, Yancheng City,Jiangsu Province PR China

- Wechat/What's app:+86-15895199590

- Mobilephone No:+86-18066199608

- Email: Sales@wellhead.cn

Products

Quick Link

News Center

Mobile terminal

+ 86-0515-88429333

+ 86-0515-88429333