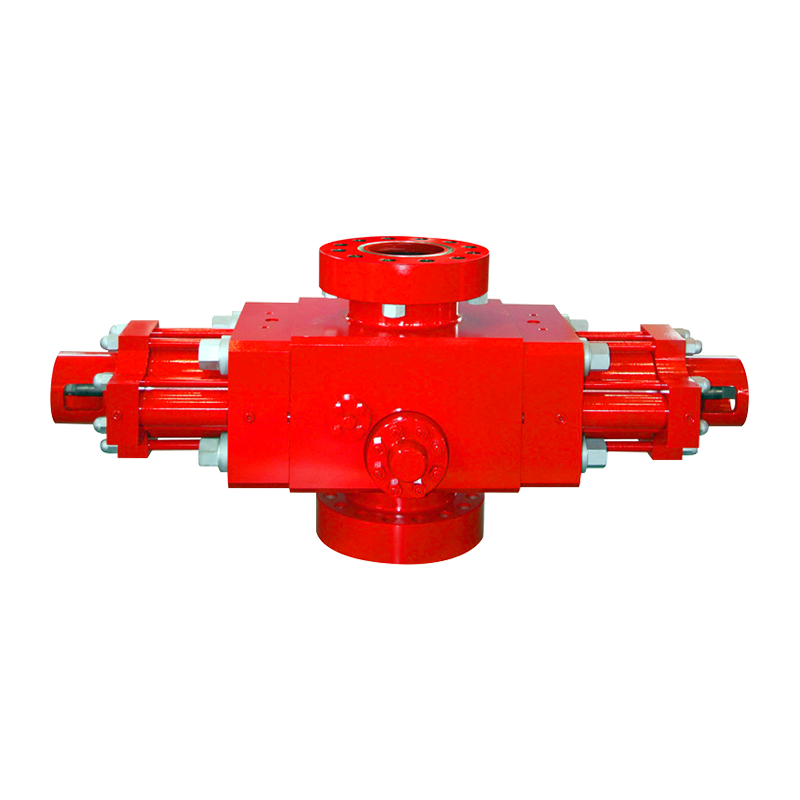

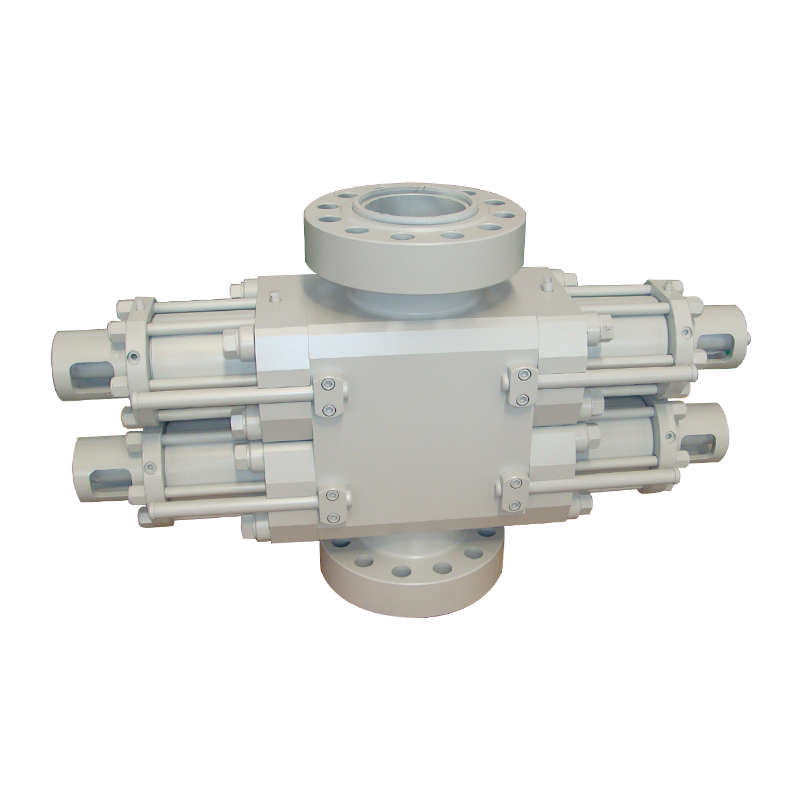

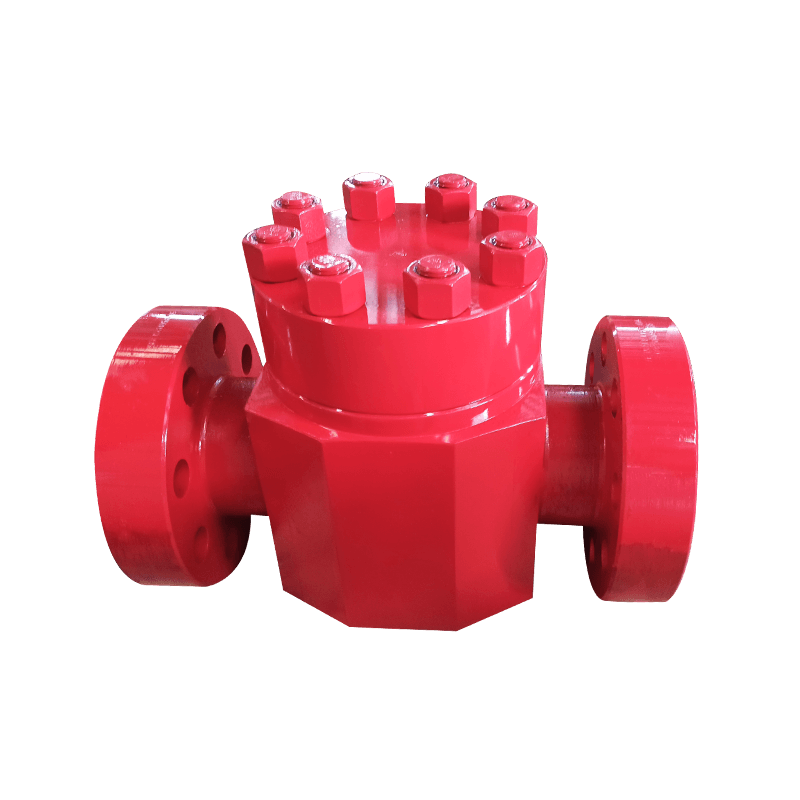

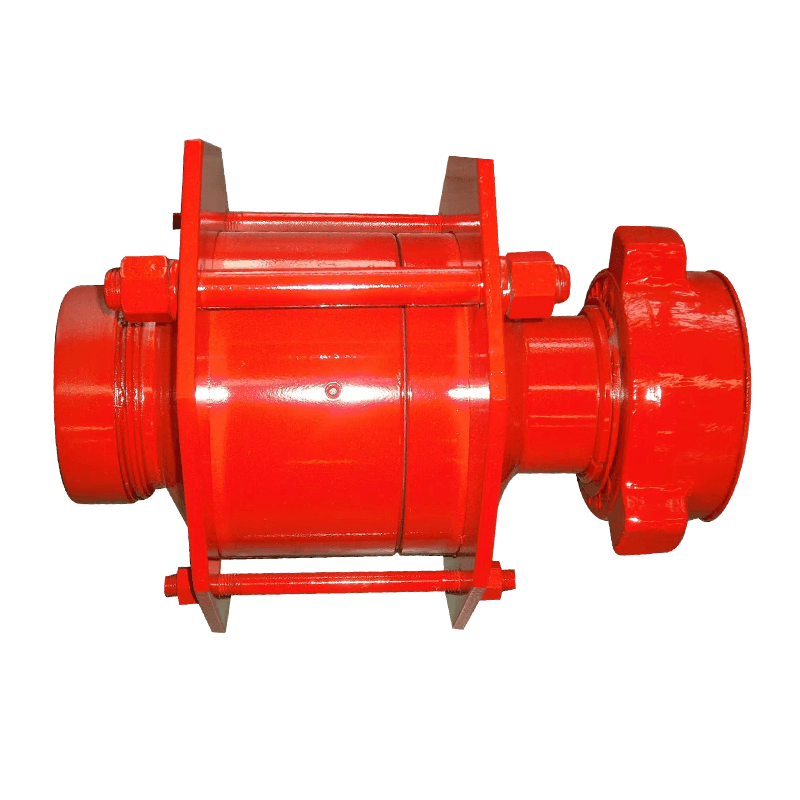

In the field of oil and gas production and transportation, Flowhead Assembly can be understood as a collection of precision-designed equipment and components that participate in key links such as fluid control, monitoring, separation and transportation. These components include but are not limited to wellhead devices, fluid control valves, flow meters, pressure sensors, separators, and related pipes and connectors. The main function of Flowhead Assembly is to ensure that oil and gas fluids can flow stably and efficiently during the production process and remain safe and leak-free during transportation.

During the oil and gas production stage, Flowhead Assembly uses precise fluid control technology to achieve precise control of wellhead fluid flow, pressure and temperature. This not only helps to improve recovery, but also reduces energy waste and environmental pollution.

The sensors and Internet of Things technology integrated in Flowhead Assembly provide real-time data monitoring and early warning functions for oil and gas production. By real-time monitoring of key parameters such as wellhead pressure, temperature, flow and fluid composition, the system can promptly detect potential production problems such as blockage, leakage or abnormal formation pressure, and automatically trigger the early warning mechanism to provide timely decision support for operators.

The oil, gas and water mixture produced during oil and gas extraction needs to be effectively separated and processed to recover high-quality oil and gas resources. The separator components in Flowhead Assembly use advanced separation technologies such as gravity separation, centrifugal separation or chemical separation to ensure efficient recovery of oil and gas and recycling of water resources. This not only improves extraction efficiency, but also reduces subsequent processing costs and environmental risks.

Oil and gas transportation is an important link in the oil and gas industry, and its safety and reliability are directly related to the stable operation of the entire industry chain. Flowhead Assembly uses high-quality pipeline materials, seals and connectors to ensure that the transportation system can maintain stable performance in various harsh environments. At the same time, by optimizing the pipeline layout and reducing the number of resistance components such as elbows and valves, the energy consumption and loss in the transportation process are further reduced.

During the oil and gas transportation process, the intelligent monitoring system integrated by Flowhead Assembly can monitor the operating status of the pipeline in real time, including pressure, flow, temperature, corrosion and leakage. Through data analysis and predictive maintenance technology, the system can detect and deal with potential problems in advance to avoid unplanned downtime events. This not only improves transportation efficiency, but also reduces maintenance costs and risks.

As the world pays more and more attention to energy conservation and environmental protection, the application of Flowhead Assembly in oil and gas transportation also pays more attention to energy conservation and emission reduction. By adopting low-energy transportation equipment, optimizing operating parameters and introducing advanced energy-saving technologies, Flowhead Assembly helps reduce energy consumption and emissions in the oil and gas transportation process and promote the sustainable development of the industry.

Web Menu

Product Search

Exit Menu

News

Home / News / Industry news / Flowhead AssemblyHow can the efficiency and safety in oil and gas production and transportation be revolutionized by this comprehensive system?

Flowhead AssemblyHow can the efficiency and safety in oil and gas production and transportation be revolutionized by this comprehensive system?

If you are interested in our products, please consult us

Contact Details

- Address: No.588 Century Street,Yandu District, Yancheng City,Jiangsu Province PR China

- Wechat/What's app:+86-15895199590

- Mobilephone No:+86-18066199608

- Email: Sales03@wellhead.cn

Products

Quick Link

News Center

Mobile terminal

+ 86-0515-88429333

+ 86-0515-88429333