In the field of fluid control systems, DM Butterfly Valve has become the preferred choice in many industrial applications with its unique butterfly-shaped structure and excellent fluid control ability. The design of this valve is not only beautiful, but more importantly, it contains profound engineering principles and superb technology, ensuring efficient fluid control and regulation.

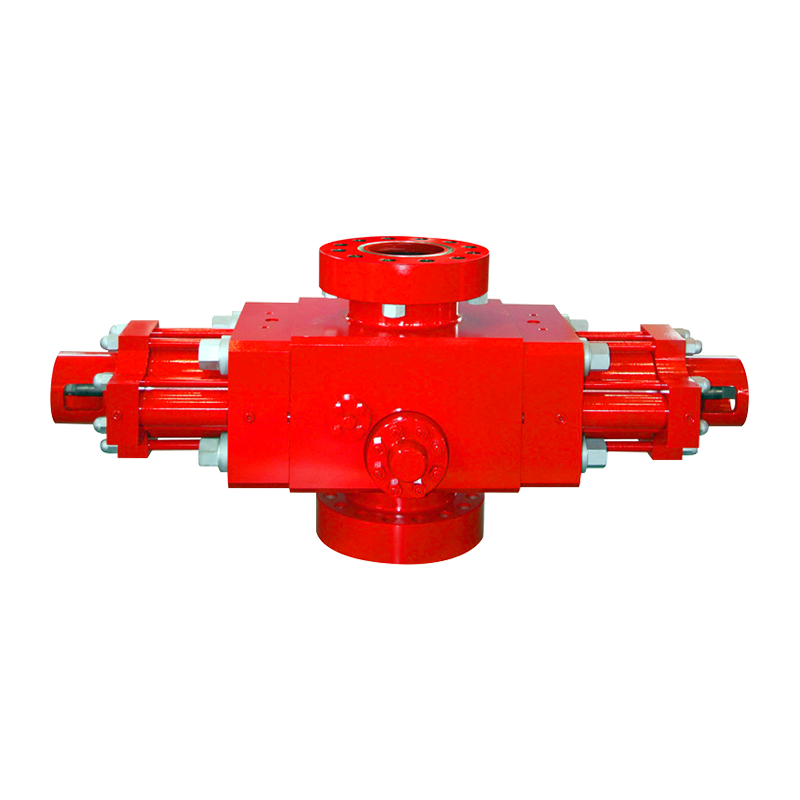

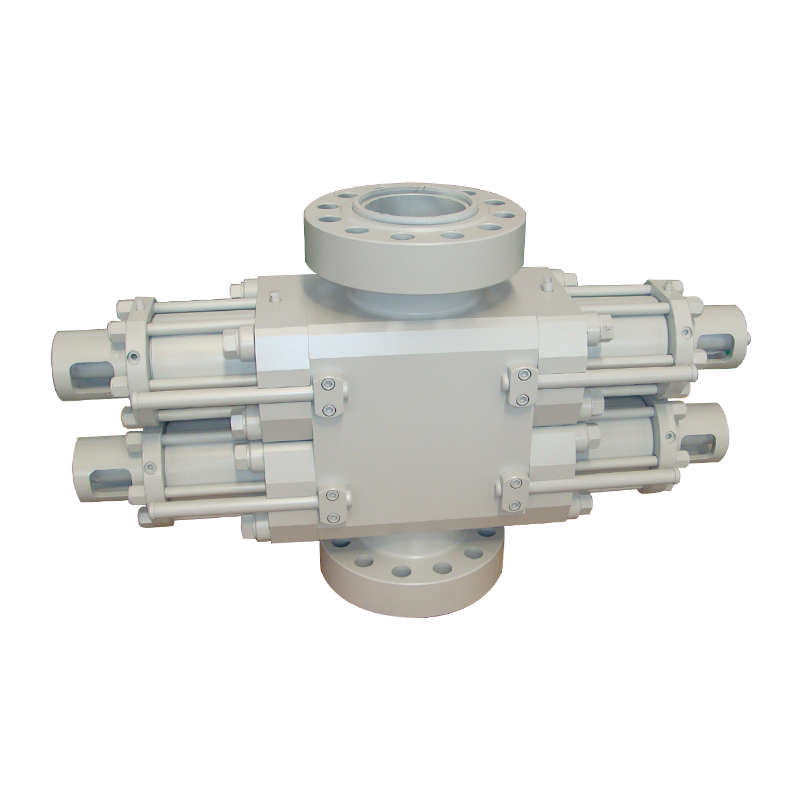

The core of the DM butterfly valve lies in its disc-shaped valve disc, also known as the butterfly plate. This butterfly plate rotates around the valve shaft and changes the angle between it and the fluid flow direction to achieve precise control of the fluid flow. When the butterfly valve is in the fully open state, the thickness of the butterfly plate becomes the only resistance when the medium flows through the valve body, which makes the fluid resistance very low and the pressure loss is small, thus ensuring good flow characteristics. This design not only improves the flow capacity of the valve, but also reduces energy consumption, which is in line with the modern industry's pursuit of high efficiency and energy saving.

In addition to basic flow control, the butterfly-shaped structure of the DM butterfly valve also gives it excellent adjustment performance. The angle of the butterfly plate can be fine-tuned, and by accurately controlling its rotation angle, fine adjustment of the fluid flow can be achieved. This flexibility makes the DM butterfly valve perform well in situations where precise flow control is required, such as pipeline systems in chemical, petroleum, natural gas and other industrial fields.

In addition, the valve body structure of the DM butterfly valve has also been carefully designed to adapt to different working conditions. Some special flow channel designs can achieve more precise medium flow control inside the valve body, improving the control accuracy and flow regulation effect of the valve. At the same time, the wing and angle control device on the valve body can further accurately control the flow direction of the medium, achieving better process effects and energy saving.

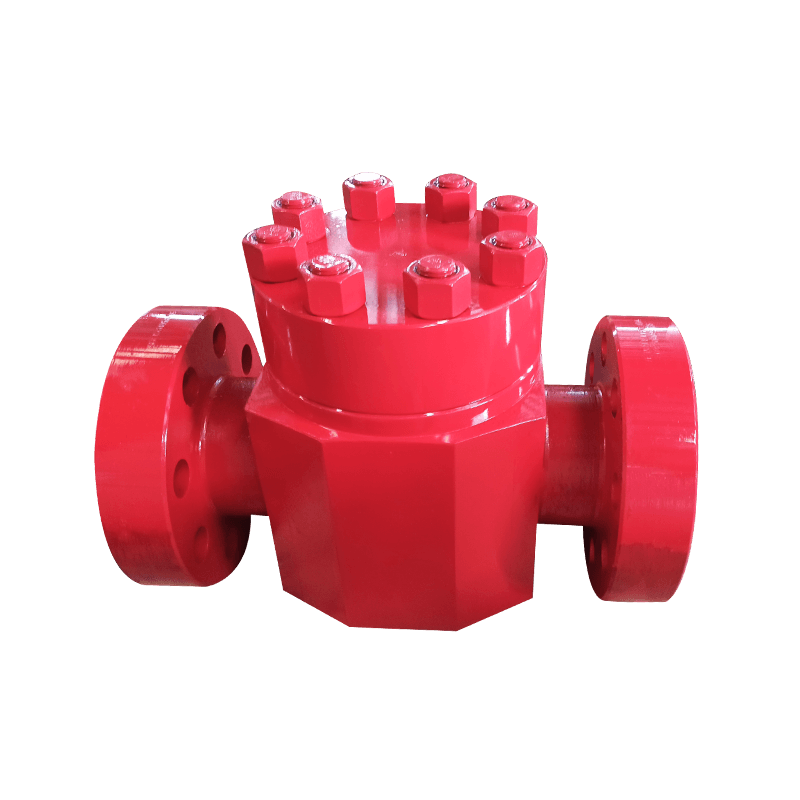

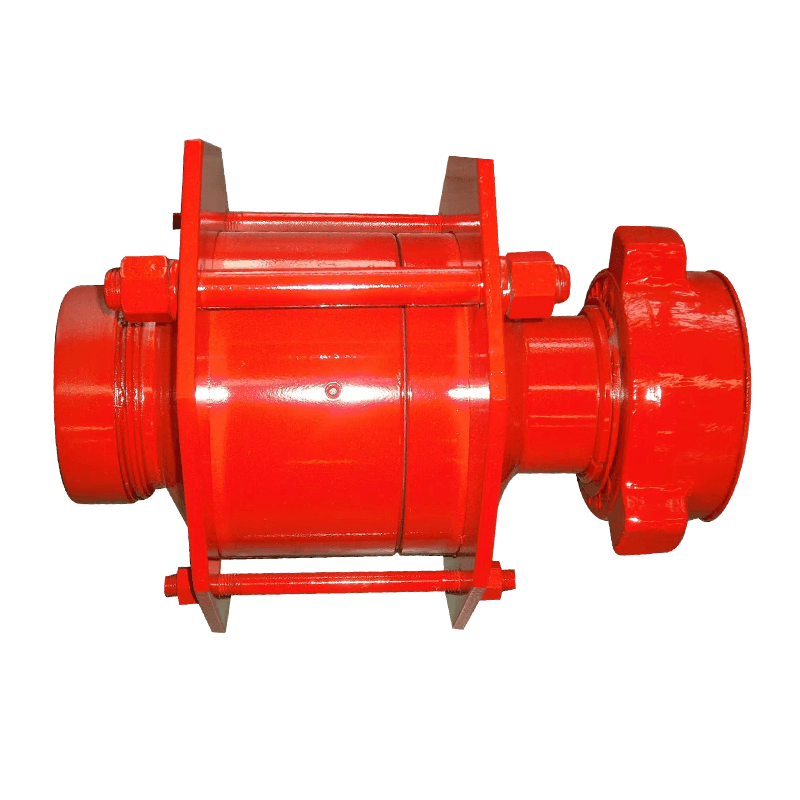

In terms of materials and manufacturing processes, the DM butterfly valve also performs well. The selection of high-quality materials and advanced manufacturing processes ensures that the valve has good sealing performance and wear resistance. This not only improves the service life and stability of the valve, but also helps to reduce leakage and failure rate of the fluid system, and improves the operating efficiency of the entire system.

It is worth mentioning that the DM butterfly valve also has excellent corrosion resistance and high pressure and high temperature resistance. This enables it to maintain excellent fluid control capabilities when handling corrosive media, high pressure media and high temperature media. This wide adaptability makes the DM butterfly valve widely used in many industries such as petrochemicals, water treatment, food, and pharmaceuticals.

Web Menu

Product Search

Exit Menu

News

Home / News / Industry news / How does the butterfly-shaped structure of DM Butterfly Valve ensure its efficient fluid control ability?

How does the butterfly-shaped structure of DM Butterfly Valve ensure its efficient fluid control ability?

If you are interested in our products, please consult us

Contact Details

- Address: No.588 Century Street,Yandu District, Yancheng City,Jiangsu Province PR China

- Wechat/What's app:+86-15895199590

- Mobilephone No:+86-18066199608

- Email: Sales03@wellhead.cn

Products

Quick Link

News Center

Mobile terminal

+ 86-0515-88429333

+ 86-0515-88429333