DM Butterfly Valve has a variety of design features that make it perform well in high-speed fluid control systems.

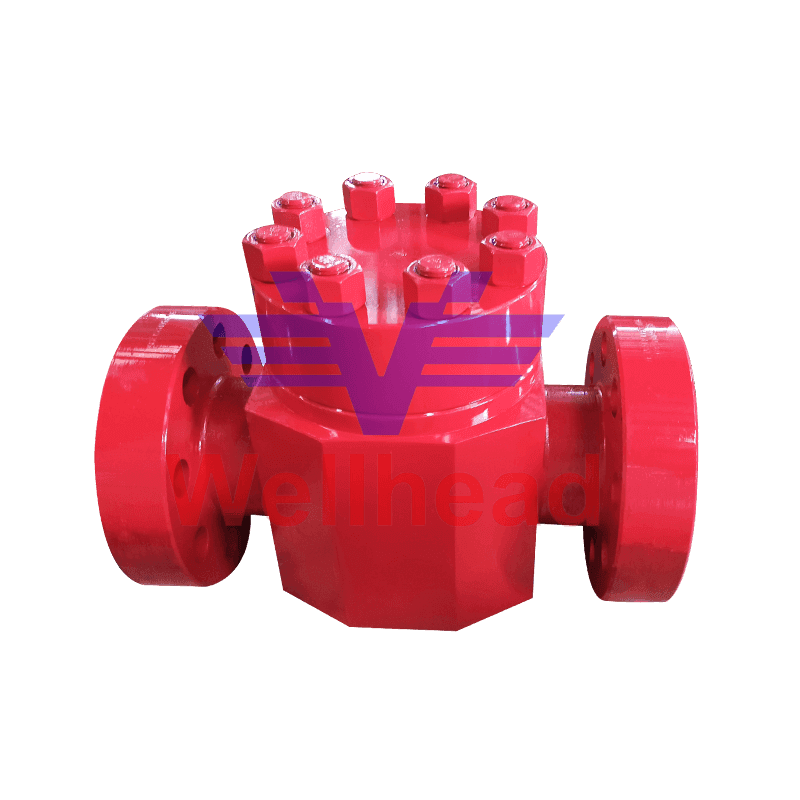

From the perspective of structural design, the valve body of the butterfly valve is cylindrical, with a short axial length and a built-in butterfly plate that rotates around the axis in the valve body. This simple structure makes the resistance of the fluid small when passing through, and can adapt to the flow of high-speed fluids and reduce pressure loss.

The butterfly plate design of the DM butterfly valve is crucial. It usually adopts a streamlined design, which can smoothly control the flow and pressure of the fluid during rotation and reduce interference with high-speed fluids. In addition, the rotation angle of the butterfly plate is usually 0°-90°, which can be opened and closed quickly. In high-speed fluid systems, the on-off and flow of the fluid can be quickly adjusted.

Sealing performance is another key design feature. Good sealing can prevent high-speed fluid leakage and ensure the stability and safety of the system. For example, the DM butterfly valve with a metal sealing structure can maintain excellent sealing performance and effectively prevent medium leakage under high temperature, high pressure and high-speed fluid conditions.

In addition, in order to meet the requirements of high-speed fluid control systems, DM butterfly valves will also be equipped with a worm gear reducer on the valve stem. This not only allows the butterfly plate to have self-locking capabilities, allowing the butterfly plate to stop at any position and accurately control the fluid flow, but also improves the operating performance of the valve, ensuring that the valve can still work stably and reliably under the impact of high-speed fluids.

News

Home / News / Industry news / What design features of DM Butterfly Valve make it suitable for high-speed fluid control systems?

What design features of DM Butterfly Valve make it suitable for high-speed fluid control systems?

If you are interested in our products, please consult us

Contact Details

- Address: No.588 Century Street,Yandu District, Yancheng City,Jiangsu Province PR China

- Wechat/What's app:+86-15895199590

- Mobilephone No:+86-18066199608

- Email: Sales@wellhead.cn

Products

Quick Link

News Center

Mobile terminal

+ 86-0515-88429333

+ 86-0515-88429333