1. Structural features

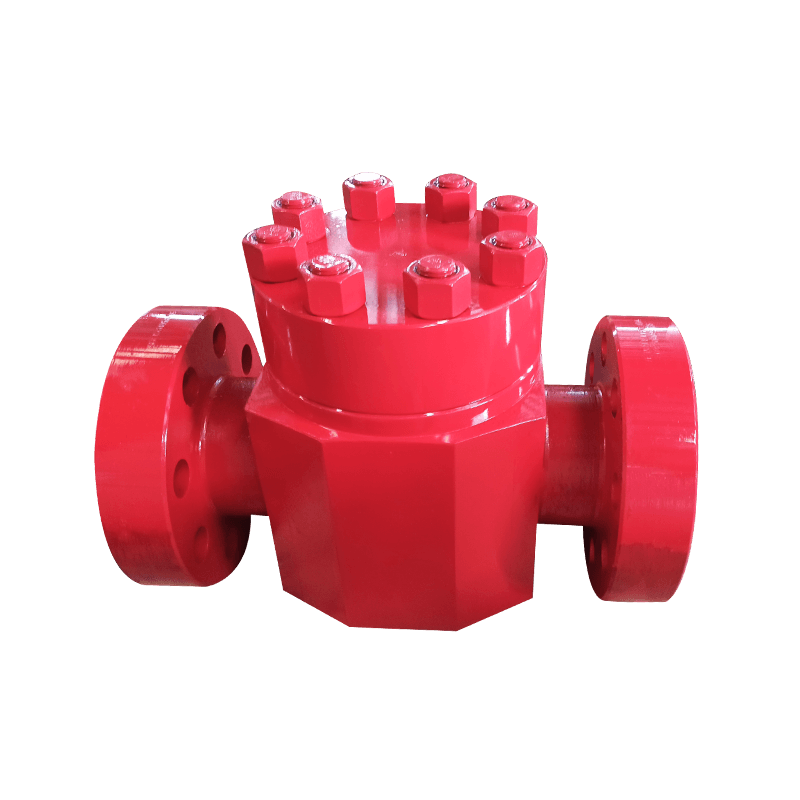

Plug: As a control element, the plug has an internal diameter, which is used to throttle the fluid

Cage: There are multiple openings arranged on the cage, and the size and arrangement of these openings are specially designed to provide the suitable combination of control and flow capacity for each application.

2. Working principle

Throttling effect: When the fluid passes through the gap between the plug and the cage, the internal diameter of the plug restricts the flow of the fluid, thereby achieving throttling. By adjusting the position or shape of the plug, the flow area of the fluid when passing through the cage opening can be changed, thereby controlling the flow.

Cage opening design: The openings on the cage are optimized to ensure stable flow control during throttling. The size and number of these openings are customized according to specific application requirements to achieve the desired flow characteristics.

Corrosion-resistant design: The plug tip and the inner wall of the cage are usually made of hard alloy (such as tungsten carbide) to improve corrosion resistance and extend service life. This design makes the Plug and Cage Choke Valve particularly suitable for highly corrosive fluids and harsh working environments.

3. Flow Control Mechanism

Precise Control: Due to the precise fit of the plug and cage, the Plug and Cage Choke Valve is able to achieve very precise flow control. By fine-tuning the position of the plug, the flow can be precisely adjusted to meet specific process requirements.

Adaptability: Multiple openings on the cage provide a variety of flow control options, allowing the valve to adapt to different flow requirements. Whether in low or high flow conditions, the desired flow characteristics can be achieved by adjusting the arrangement and size of the cage openings.

Good Stability: Due to the use of carbide materials, the valve can maintain stable performance during long-term use and is not easily affected by fluid erosion and wear. This ensures the accuracy and reliability of flow control.

Web Menu

Product Search

Exit Menu

News

How does the Plug and Cage Choke Valve achieve flow control?

If you are interested in our products, please consult us

Contact Details

- Address: No.588 Century Street,Yandu District, Yancheng City,Jiangsu Province PR China

- Wechat/What's app:+86-15895199590

- Mobilephone No:+86-18066199608

- Email: Sales03@wellhead.cn

Products

Quick Link

News Center

Mobile terminal

+ 86-0515-88429333

+ 86-0515-88429333