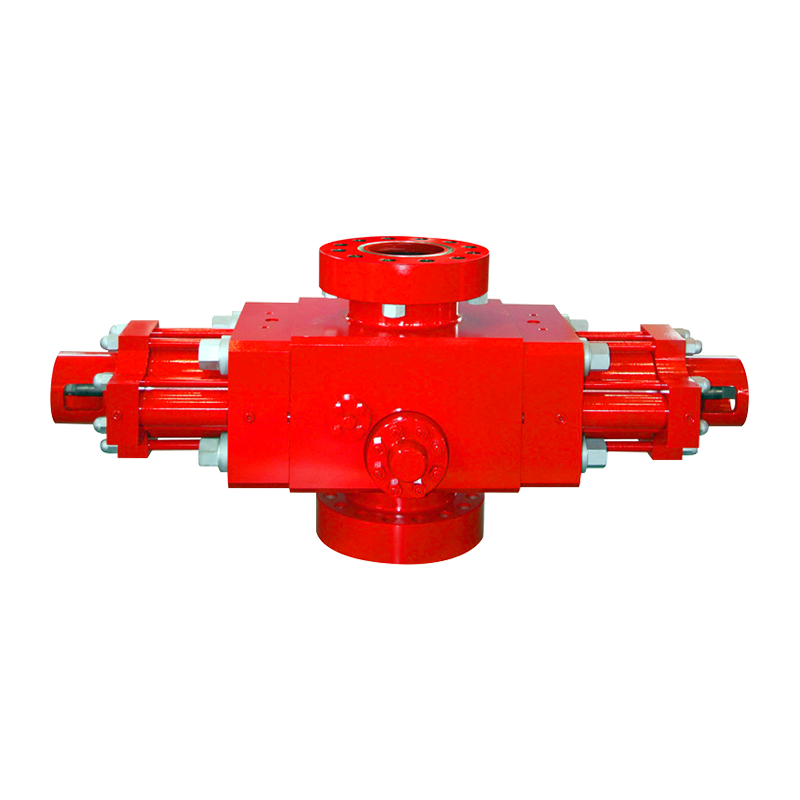

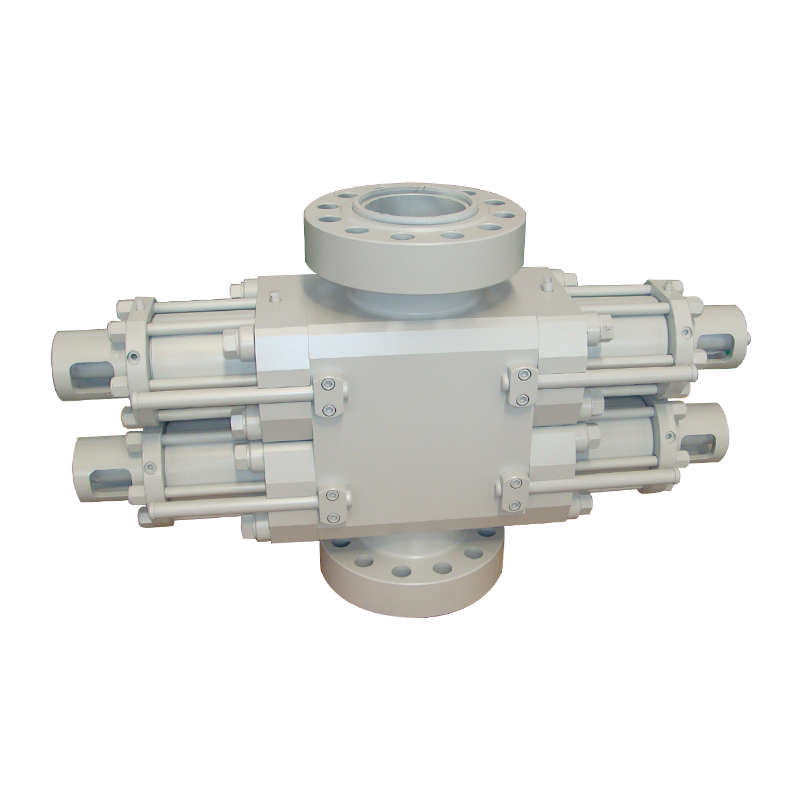

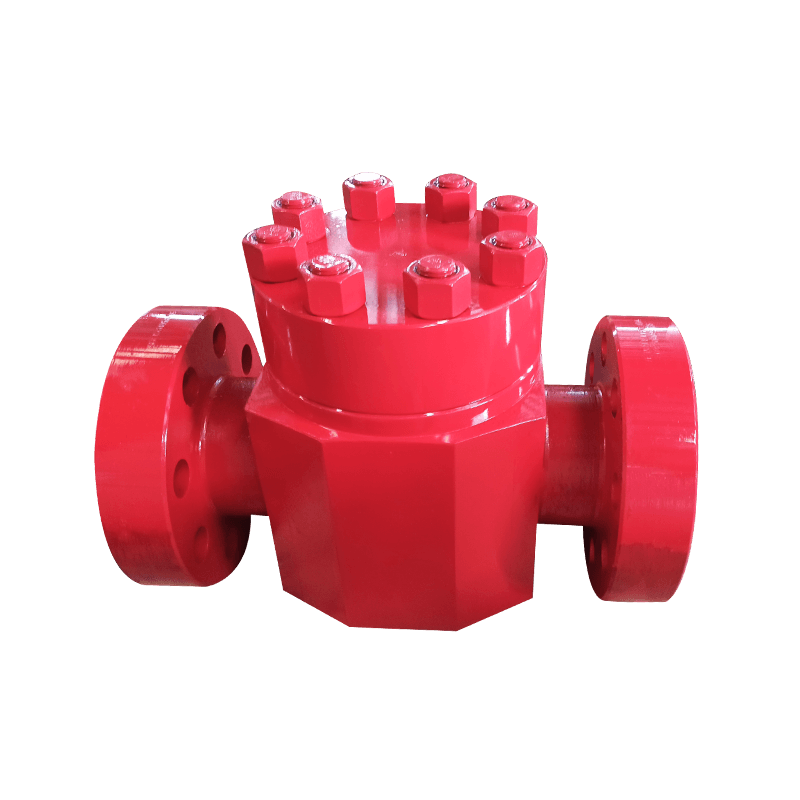

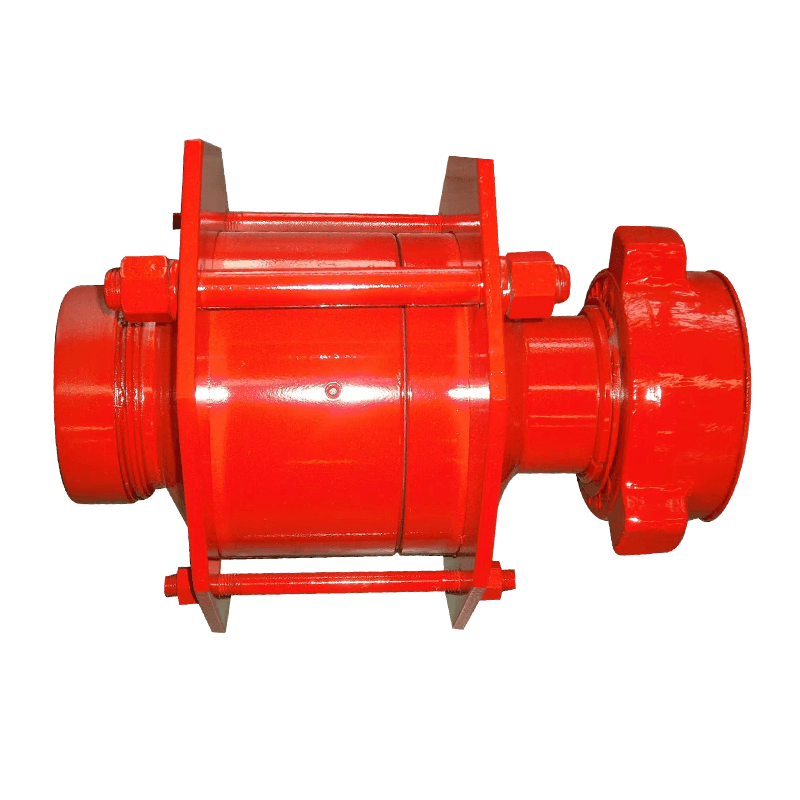

The working principle of the Pneumatic Operated Safety Valve is based on precise pneumatic control and pressure sensing mechanisms. The core is to monitor the pressure changes in the pipeline or equipment in real time through internal sensors. Once the pressure reaches or exceeds the preset safety threshold, the sensor will quickly transmit the signal to the control system. After judgment, the control system sends an opening command to the safety valve through the pneumatic control system. Subsequently, the valve flap of the safety valve opens rapidly under the action of pneumatic force, releasing excess media, thereby reducing the pressure in the pipeline or equipment and preventing equipment damage or safety accidents caused by overpressure.

The Pneumatic Operated Safety Valve can respond to pressure changes in a very short time and open or close quickly, effectively preventing accidents from expanding. Through precise control systems and regulating devices, pneumatically operated safety valves can achieve precise control of the discharge rate and amount to ensure safe and stable operation of the system. Pneumatic control systems usually adopt redundant design to improve the reliability of the system. Even in the case of partial component failure, the normal operation of the safety valve can be guaranteed. The Pneumatic Operated Safety Valve can adapt to different working media, temperature and pressure ranges, meet diverse industrial needs, and has a simple structure and is easy to maintain and repair. At the same time, many modern pneumatic safety valves are also equipped with fault alarm and recording functions, which facilitates maintenance personnel to find and solve problems in time.

In high-risk industries such as petrochemicals and natural gas transportation, the importance of Pneumatic Operated Safety Valve is self-evident. They are not only the last line of defense to prevent equipment from overpressure damage, but also key equipment to ensure personnel safety and environmental safety. When pipelines or equipment are overpressured due to various reasons (such as operating errors, equipment failures, natural disasters, etc.), pneumatic operated safety valves can respond and release excess pressure to prevent further expansion of accidents. This instant and effective pressure control is of great significance to reducing property losses, protecting personnel lives, and maintaining environmental ecological balance.

Web Menu

Product Search

Exit Menu

News

Home / News / Industry news / How does the Pneumatic Operated Safety Valve respond and guard the last line of defense in industrial safety?

How does the Pneumatic Operated Safety Valve respond and guard the last line of defense in industrial safety?

If you are interested in our products, please consult us

Contact Details

- Address: No.588 Century Street,Yandu District, Yancheng City,Jiangsu Province PR China

- Wechat/What's app:+86-15895199590

- Mobilephone No:+86-18066199608

- Email: Sales03@wellhead.cn

Products

Quick Link

News Center

Mobile terminal

+ 86-0515-88429333

+ 86-0515-88429333