In the complex and crucial field of oil and gas well exploitation, the Wellhead assy and X-mas Tree play indispensable and distinct roles.

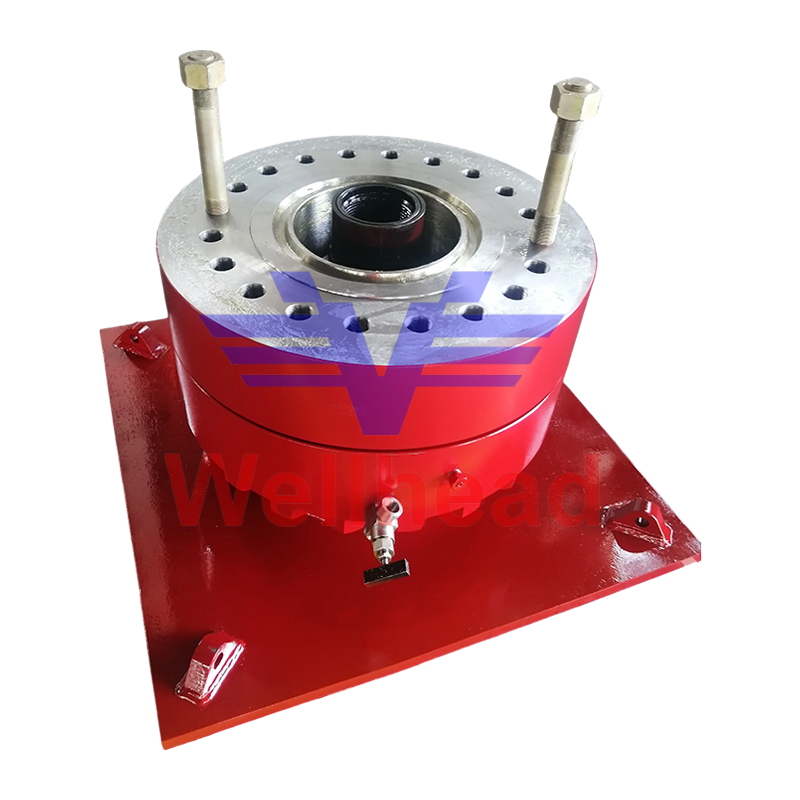

The Wellhead assy is the fundamental connection point between the subsurface wellbore and the surface equipment. It serves as a structural anchor, providing stability and support for the entire well system. Comprising a variety of components such as casing hangers, tubing hangers, and valves, it ensures the proper alignment and sealing of the casing and tubing strings. The casing hanger, for example, securely holds the casing in place, preventing it from collapsing or shifting under the immense pressure from the surrounding rock formations and the fluids within the well. The tubing hanger, on the other hand, supports the tubing through which the oil and gas are transported to the surface. Valves within the Wellhead assy are essential for controlling the flow of fluids. They can be used to shut in the well in case of emergencies, such as a blowout or a leak, or to regulate the production rate of the well. By precisely adjusting the valve openings, operators can optimize the extraction of hydrocarbons while maintaining the safety and integrity of the well.

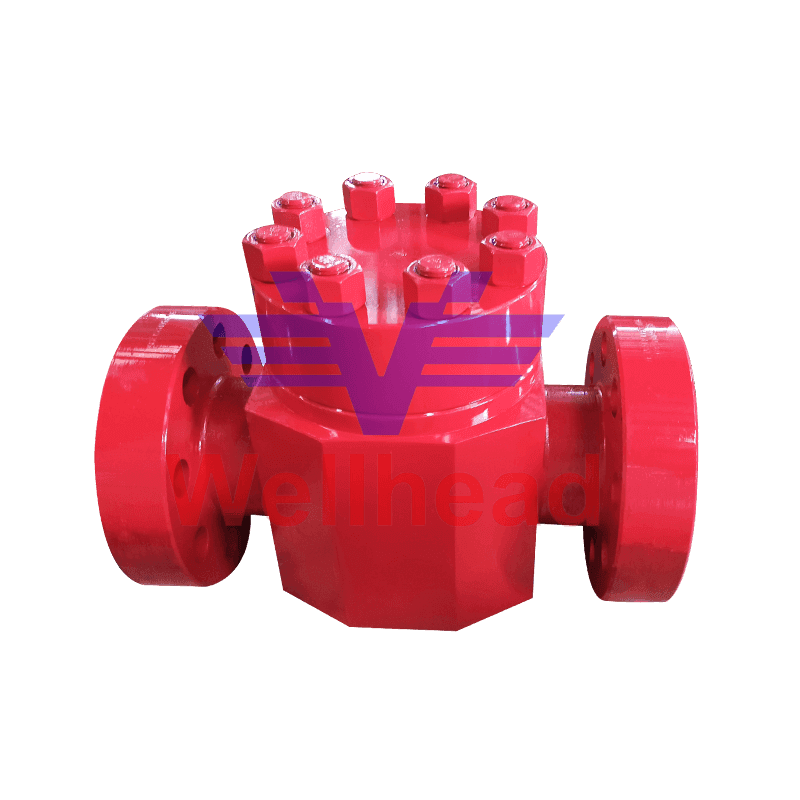

The X-mas Tree, named for its resemblance to a Christmas tree, is installed atop the Wellhead assy. It is a complex network of valves, fittings, and gauges that provides the interface for all surface operations related to the well. It houses multiple valves that control the flow of oil, gas, and water from the well. These valves are designed to handle high pressures and can be operated remotely or manually. For instance, the master valve is a critical component that can completely shut off the flow from the well. The choke valve, on the other hand, is used to regulate the flow rate and pressure of the produced fluids. The X-mas Tree also includes gauges that measure parameters such as pressure, temperature, and flow rate. These measurements are crucial for monitoring the performance of the well and making informed decisions about production optimization. Additionally, it provides access points for injecting chemicals or fluids into the well for various purposes, such as enhancing oil recovery or maintaining the wellbility.

News

Home / News / Industry news / Wellhead assy and X-mas Tree: What specific role do they play in oil and gas well production?

Wellhead assy and X-mas Tree: What specific role do they play in oil and gas well production?

If you are interested in our products, please consult us

Contact Details

- Address: No.588 Century Street,Yandu District, Yancheng City,Jiangsu Province PR China

- Wechat/What's app:+86-15895199590

- Mobilephone No:+86-18066199608

- Email: Sales@wellhead.cn

Products

Quick Link

News Center

Mobile terminal

+ 86-0515-88429333

+ 86-0515-88429333