In the field of oil and gas mining, Wellhead assy and X-mas Tree show significantly different application characteristics in deep-sea and land mining.

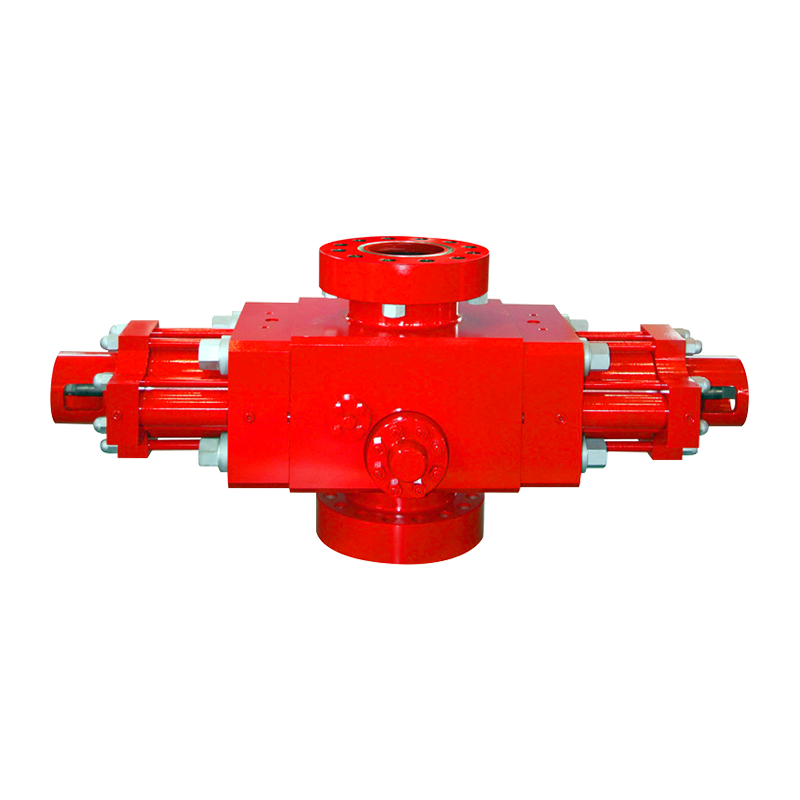

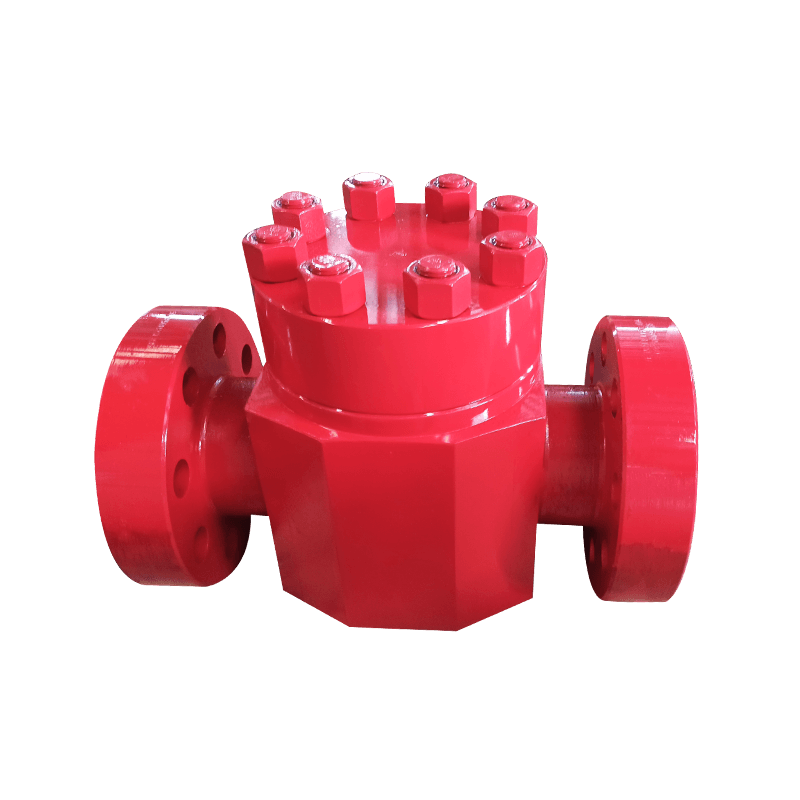

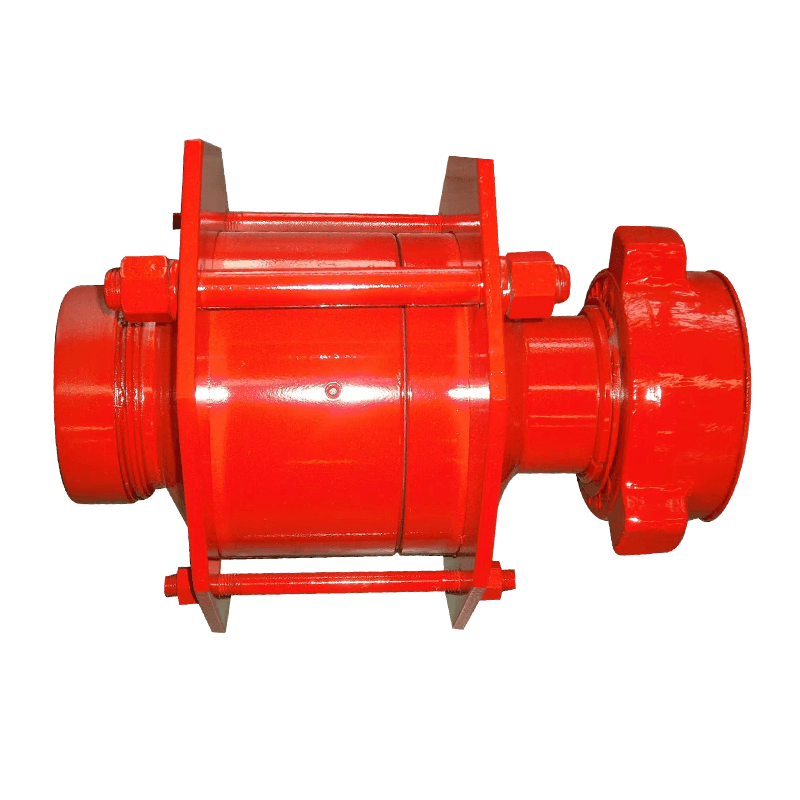

For land mining, the installation environment of wellhead assembly and Christmas tree is relatively stable and convenient. The geological conditions on land are usually clear, and the infrastructure construction is relatively easy. As a key part connecting the downhole oil pipe and the ground equipment, the design of the wellhead assembly focuses on firmness and stability to cope with various possible mechanical stresses and natural environmental influences on the ground. It can effectively control the pressure of the oil well, ensure that crude oil and natural gas are smoothly mined from underground to the ground, and perform preliminary separation and metering. In land mining, the Christmas tree mainly bears the functions of controlling oil and gas flow, regulating pressure and performing wellhead operations. Its operation is relatively convenient, and maintenance personnel can more easily perform daily inspections, equipment maintenance and fault handling. For example, in some land oil fields, staff can regularly inspect and maintain the valves of the Christmas tree, replace seals and other vulnerable parts in time, and ensure the normal production of the oil well.

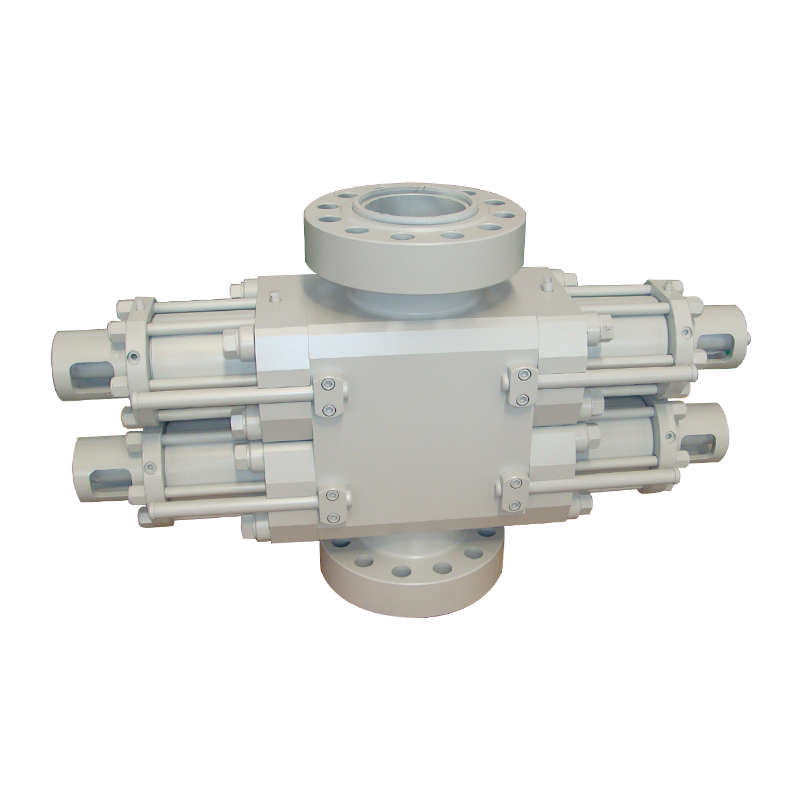

In deep-sea mining, the wellhead assembly and the Christmas tree face extremely harsh and complex environmental challenges. The high pressure, low temperature, highly corrosive seawater and complex marine geological conditions in the deep sea all place extremely high demands on the equipment. The wellhead assembly needs to have super strong pressure resistance, and its sealing performance must be foolproof to prevent crude oil and natural gas from leaking under high pressure. At the same time, due to the high cost and difficulty of deep-sea operations, the wellhead assembly is often designed to be more compact and integrated to reduce the installation and maintenance workload of the equipment. The application of Christmas trees in deep-sea mining is also more complex. It not only needs to have precise pressure control and flow regulation functions, but also needs to be closely integrated with the remote monitoring system. Because it is difficult for personnel to dive frequently for on-site operations in deep-sea environments, the Christmas tree has a higher degree of automation and intelligence. For example, through a remote control system, the Christmas tree of a deep-sea oil well can be switched on and off, and the pressure can be adjusted on the offshore platform or land control center, the production status of the oil well can be monitored in real time, and possible abnormal situations can be responded to in a timely manner.

In addition, in deep-sea mining, the installation and recovery process of the wellhead assembly and Christmas tree is also very different from that on land. Deep-sea operations require special marine engineering equipment, such as drilling ships, underwater robots, etc. for installation and maintenance. The installation accuracy of the equipment is extremely high, and the entire process needs to strictly follow the marine engineering safety regulations to avoid marine accidents. The installation and recovery of land mining is relatively simple, and can usually be completed using conventional engineering machinery and equipment.

Our company has fully considered the different needs of deep-sea and land mining in the research and development and production of wellhead assemblies and Christmas trees. With advanced technology and rich experience, we provide customized, high-performance equipment solutions for global oil and gas mining companies, whether it is the extreme challenge of the deep sea or the stable production on land, to ensure the efficiency and safety of mining operations.

Web Menu

Product Search

Exit Menu

News

Home / News / Industry news / What are the different applications of Wellhead assy and X-mas Tree in deep-sea and land mining?

What are the different applications of Wellhead assy and X-mas Tree in deep-sea and land mining?

If you are interested in our products, please consult us

Contact Details

- Address: No.588 Century Street,Yandu District, Yancheng City,Jiangsu Province PR China

- Wechat/What's app:+86-15895199590

- Mobilephone No:+86-18066199608

- Email: Sales03@wellhead.cn

Products

Quick Link

News Center

Mobile terminal

+ 86-0515-88429333

+ 86-0515-88429333