In the world of oil and gas exploration and production, hydraulic fracturing has become a widely used technique. And at the heart of this process is the frac head, a critical component that plays a vital role in ensuring the success of hydraulic fracturing operations.

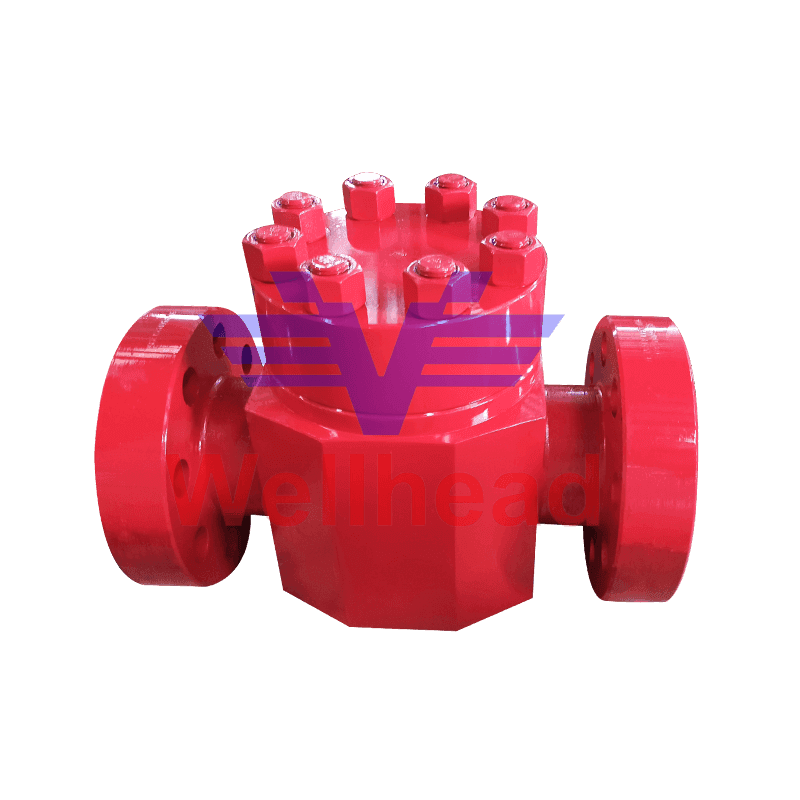

The frac head is responsible for directing the flow of high-pressure fluids into the wellbore. It acts as a connection point between the surface equipment and the well, allowing the fracturing fluid to be pumped down into the formation with precision and control.

One of the key functions of the frac head is to regulate the pressure and flow rate of the fracturing fluid. This is essential for creating the fractures in the rock formation that allow the oil and gas to flow more freely. By controlling the pressure and flow, the frac head can ensure that the fracturing process is carried out safely and efficiently.

In addition to regulating pressure and flow, the frac head also provides a means of injecting proppants into the formation. Proppants are small particles, such as sand or ceramic beads, that are used to keep the fractures open after the fracturing fluid is withdrawn. The frac head is designed to mix the proppants with the fracturing fluid and inject them into the well at the appropriate time.

Another important role of the frac head is to monitor and control the fracturing process. It is equipped with sensors and instrumentation that provide real-time data on pressure, flow rate, and other parameters. This information is used by operators to make adjustments and ensure that the fracturing operation is proceeding as planned.

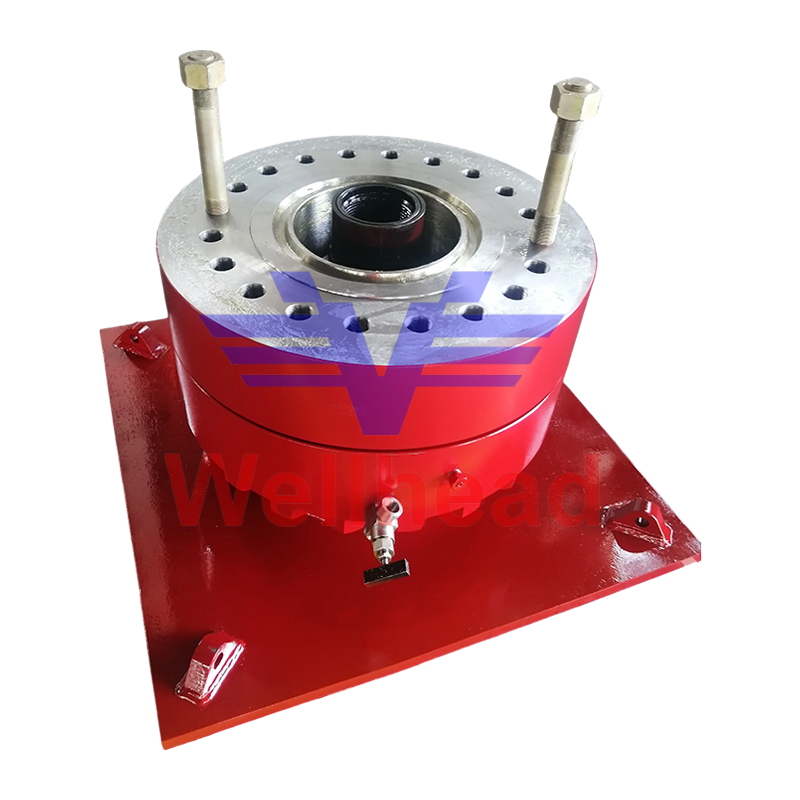

The durability and reliability of the frac head are also crucial. Hydraulic fracturing operations involve extremely high pressures and harsh environments, so the frac head must be able to withstand these conditions without failure. It is typically made of high-strength materials and is designed to withstand the rigors of continuous use.

Furthermore, the frac head must be easy to install and maintain. Quick and efficient installation is essential to minimize downtime and keep the fracturing operation on schedule. Regular maintenance and inspection are also necessary to ensure that the frac head is functioning properly and to detect any potential issues before they become major problems.

News

What Role Does a Frac Head Play in Hydraulic Fracturing Operations?

If you are interested in our products, please consult us

Contact Details

- Address: No.588 Century Street,Yandu District, Yancheng City,Jiangsu Province PR China

- Wechat/What's app:+86-15895199590

- Mobilephone No:+86-18066199608

- Email: Sales03@wellhead.cn

- Sales@wellhead.cn

Products

Quick Link

News Center

Mobile terminal

+ 86-0515-88429333

+ 86-0515-88429333