In the complex process of hydraulic fracturing, the design of a Frac Head plays a crucial role in determining the efficiency of fracturing fluids.

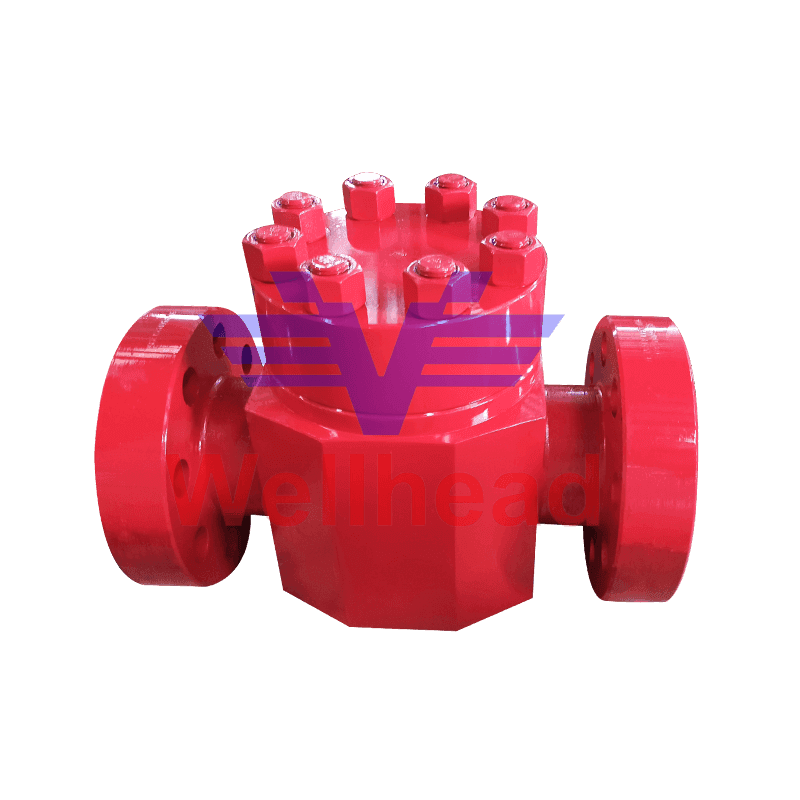

The structure of the frac head directly influences the flow path of the fracturing fluids. A well - designed frac head ensures a smooth and even flow of fluids into the wellbore. For example, it may have optimized channels and ports that minimize turbulence. When fracturing fluids flow without excessive turbulence, they can maintain a more consistent pressure, which is essential for effectively creating and extending fractures in the rock formation. This smooth flow also reduces the risk of premature degradation of the fracturing fluids, as violent turbulence can cause shearing and breakdown of the fluid components.

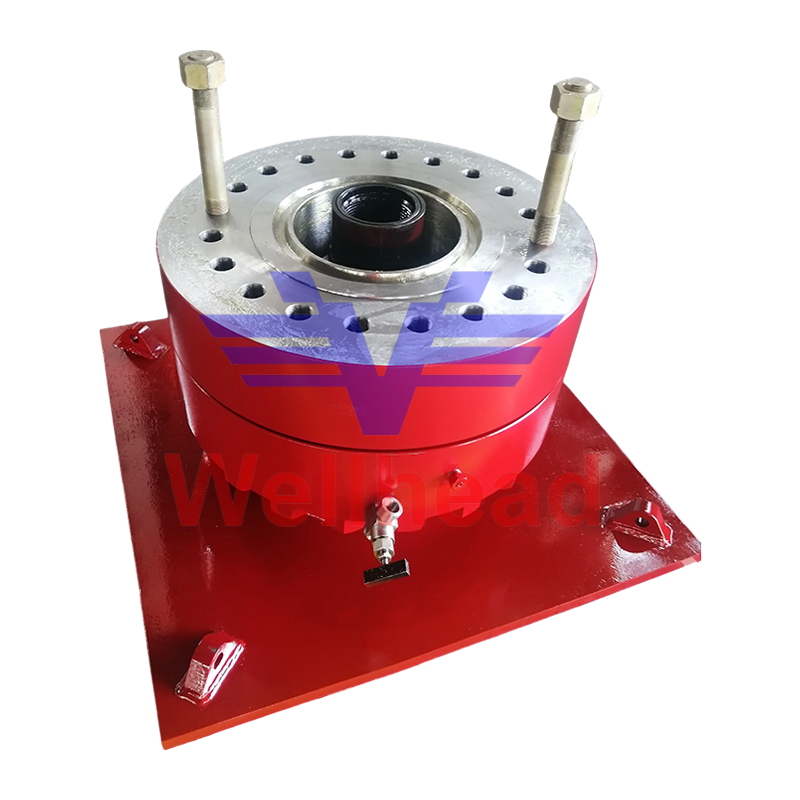

The connection points within the frac head are also vital. High - quality connections ensure that there are no leaks or pressure losses. In a hydraulic fracturing operation, any leakage of fracturing fluids can lead to inefficiencies, as it reduces the amount of fluid reaching the target formation. The design of the connection interfaces, whether they are threaded connections or specialized coupling mechanisms, should provide a tight seal even under high - pressure conditions. This allows the fracturing fluids to be directed precisely where they are needed without any wastage.

The number and configuration of injection points on the frac head can significantly impact fluid efficiency. Multiple injection points can distribute the fracturing fluids more evenly across the wellbore, ensuring that different areas of the formation receive an appropriate amount of fluid. This can lead to more uniform fractures, which is beneficial for maximizing the productivity of the well. The design may also incorporate adjustable injection points to allow for customization based on the specific characteristics of the formation being fractured. For example, in a heterogeneous formation, the ability to control the flow rate and direction of the fracturing fluids at different injection points can help target areas with different rock properties more effectively.

Material selection for the frac head is another critical factor. The materials should be able to withstand the harsh conditions of high - pressure, corrosive fracturing fluids. Corrosion - resistant materials prevent the degradation of the frac head itself, which could otherwise introduce contaminants into the fracturing fluids or disrupt the flow. Additionally, materials with high strength and durability ensure that the frac head can maintain its structural integrity throughout the fracturing process, which is essential for consistent performance.

News

Home / News / Industry news / How Can the Design of a Frac Head Impact the Efficiency of Fracturing Fluids?

How Can the Design of a Frac Head Impact the Efficiency of Fracturing Fluids?

If you are interested in our products, please consult us

Contact Details

- Address: No.588 Century Street,Yandu District, Yancheng City,Jiangsu Province PR China

- Wechat/What's app:+86-15895199590

- Mobilephone No:+86-18066199608

- Email: Sales03@wellhead.cn

- Sales@wellhead.cn

Products

Quick Link

News Center

Mobile terminal

+ 86-0515-88429333

+ 86-0515-88429333